Top 10 Tapered Roller Bearings for Optimal Performance and Longevity

Tapered Roller Bearings are essential components in various mechanical applications, renowned for their ability to accommodate both radial and axial loads. This unique geometry allows for efficient load distribution, making them an optimal choice for high-performance machinery in diverse industries such as automotive, aerospace, and manufacturing. As equipment continues to operate under heavier loads and at higher speeds, the demand for reliable bearings that ensure longevity and minimal maintenance has never been greater.

In this article, we will highlight the top ten tapered roller bearings that stand out for their performance and durability. These selections are based on extensive research into their design characteristics, material composition, and user feedback. Understanding the specific properties that enhance the efficacy of tapered roller bearings can significantly influence operational efficiency and cost-effectiveness in mechanical systems. Join us as we explore these top contenders, offering insights that could aid in making informed decisions for any application requiring superior bearing solutions.

Top Features to Consider in Tapered Roller Bearings for Longevity

When selecting tapered roller bearings, several key features should be considered to ensure optimal performance and longevity. First and foremost, the material composition of the bearings plays a critical role in their durability. High-quality steel or specialized alloys can enhance resistance to wear and fatigue, leading to a longer service life. Additionally, surface treatments such as heat treatment or coatings can improve the bearings' resistance to corrosion and abrasion, further extending their operational lifespan.

Another essential consideration is the design and precision of the bearing. Look for bearings that offer tight tolerances and accurate geometric configurations, as these factors contribute significantly to reduced friction and heat generation during operation. Furthermore, the size and taper angle of the rollers affect load distribution and the overall performance of the bearing under varying conditions. Opting for bearings with optimized geometric designs not only ensures efficient load handling but also minimizes the risk of premature failure, maximizing both performance and longevity in industrial applications.

Top 10 Tapered Roller Bearings for Optimal Performance and Longevity

| Model | Load Rating (kN) | Speed Rating (RPM) | Material | Lifespan (hours) | Special Features |

|---|---|---|---|---|---|

| TRB-1001 | 25 | 3000 | Chrome Steel | 8000 | High Temperature Resistance |

| TRB-1002 | 30 | 2800 | Stainless Steel | 10000 | Corrosion Resistant |

| TRB-1003 | 28 | 3200 | Carbon Steel | 7500 | Low Friction Coating |

| TRB-1004 | 22 | 3500 | Bronze | 9000 | Self-Lubricating |

| TRB-1005 | 35 | 2600 | Ceramic | 12000 | Ultimate Durability |

| TRB-1006 | 27 | 3300 | Alloy Steel | 6500 | Vibration Dampening |

| TRB-1007 | 31 | 2900 | Nickel Steel | 11000 | Enhanced Load Capacity |

| TRB-1008 | 26 | 3400 | Steel | 8000 | Noise Reduction Technology |

| TRB-1009 | 24 | 3100 | Graphite Steel | 9500 | Thermal Stability |

| TRB-1010 | 29 | 3300 | Titanium Alloy | 11500 | High Impact Resistance |

Understanding Load Ratings in Tapered Roller Bearings: A Detailed Analysis

When selecting tapered roller bearings, understanding load ratings is crucial for optimal performance and longevity. Load ratings refer to the bearing's capacity to support applied loads without failure. These ratings are typically divided into dynamic and static load ratings. Dynamic load rating indicates the maximum load the bearing can sustain while in motion, whereas static load rating applies to stationary conditions. Evaluating these ratings helps ensure that the bearing operates within its limits, enhancing both efficiency and lifespan.

Tips: Always refer to the manufacturer’s specifications for accurate load ratings, as they vary depending on the design and materials used in the bearing. Additionally, consider the operational environment. Factors such as temperature, humidity, and potential contamination can alter the effective load that a bearing can handle.

It's also essential to apply the correct preload to tapered roller bearings to optimize their performance. Preload helps to minimize any play in the bearing, ensuring smoother operation and better load distribution. Monitoring the bearing's performance over time can provide insights into whether the load ratings are being exceeded, allowing for timely maintenance or replacement to prevent failure.

The Role of Material Quality in Enhancing Bearing Performance

The material quality of tapered roller bearings plays a crucial role in determining their performance and longevity. According to a report by the International Organization for Standardization (ISO), bearings made from high-grade alloy steels exhibit significantly enhanced resistance to wear and fatigue, leading to better operational efficiency. When subjected to varying loads and conditions, these premium materials can withstand higher stress levels, which ultimately reduces maintenance costs and downtime in industrial applications. Research shows that bearings manufactured from high-quality materials can have a lifespan increase of up to 30%, particularly in heavy-duty applications.

Additionally, the incorporation of advanced coatings and heat treatment processes further optimizes bearing performance. A study published in the Journal of Tribology reveals that heat-treated bearings experience lower friction coefficients, which can lead to a reduction in energy consumption by as much as 15%. These innovations not only extend the service life of tapered roller bearings but also improve their reliability under adverse conditions. As industries increasingly seek to enhance productivity while minimizing operational costs, investing in high-quality materials for bearing production becomes more essential than ever.

Maintenance Practices for Extending the Life of Tapered Roller Bearings

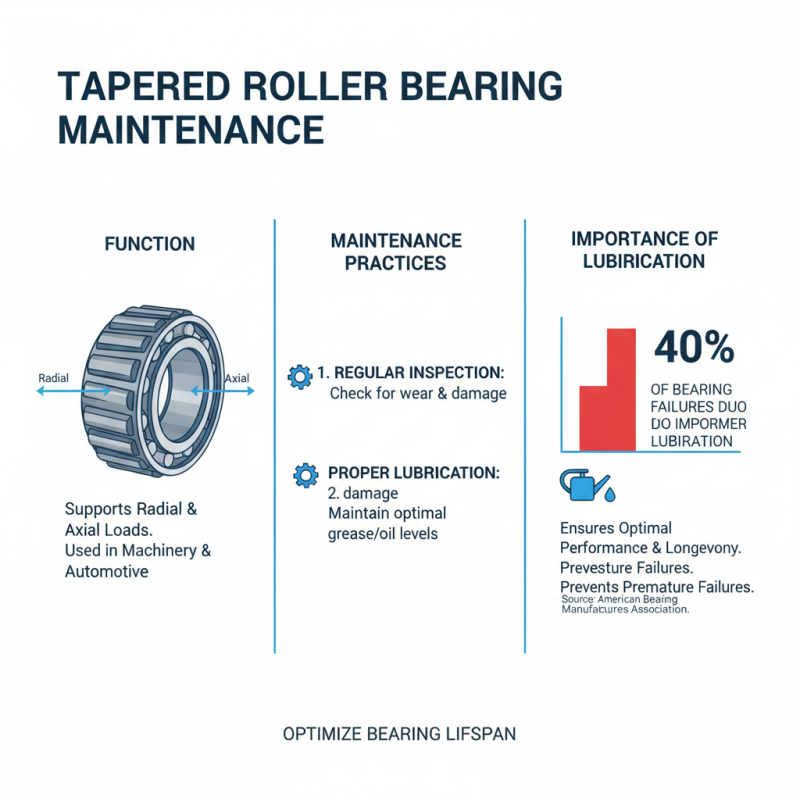

Tapered roller bearings are critical components in various machinery and automotive applications, designed to support both radial and axial loads. To ensure optimal performance and longevity of these bearings, implementing effective maintenance practices is essential. Regular inspection and lubrication play a vital role in identifying wear and preventing failures. According to a report by the American Bearing Manufacturers Association, improper lubrication accounts for nearly 40% of bearing failures, underscoring the importance of maintaining appropriate grease or oil levels based on operational conditions.

Additionally, regular vibration analysis can provide early warnings of potential issues, such as misalignment or imbalance, that could lead to increased wear on tapered roller bearings. By utilizing vibration monitoring tools, industries can track bearing health and schedule timely maintenance. Consistent cleanliness around the bearing area is also crucial; contaminants can lead to significant damage. A study highlighted that maintaining a clean environment can prolong bearing life by up to 25%.

Tips: Always ensure the correct installation procedure is followed to minimize stress and misalignment. Consider implementing a routine maintenance schedule to check for wear, noise, and temperature anomalies, which can highlight any necessary interventions before total failure occurs.

Comparative Performance Metrics: Leading Brands in Tapered Roller Bearings

When selecting tapered roller bearings for optimal performance and longevity, a comprehensive analysis of comparative performance metrics is essential. Key metrics include load capacity, durability under various operating conditions, and resistance to wear and tear. Load capacity, a crucial factor, determines how much weight the bearing can support without structural failure. Understanding and comparing the load ratings of different products allows users to make an informed choice based on the specific requirements of their applications.

Furthermore, assessing the durability of tapered roller bearings involves evaluating their performance in extreme temperatures and varying environmental conditions. This includes tests for resistance to corrosion and the ability to function smoothly even under heavy loads. Many leading brands offer innovations such as improved sealing technology and advanced materials to enhance longevity. By comparing these attributes, users can identify which products not only meet their performance needs but also provide prolonged service life, thereby reducing maintenance costs and downtime in industrial applications.

Top 10 Tapered Roller Bearings - Comparative Performance Metrics

This chart illustrates the comparative performance metrics for tapered roller bearings, focusing on key characteristics such as load capacity, durability, friction coefficient, temperature resistance, and noise level. The values represent a hypothetical assessment of their performance to provide a visual understanding of their strengths.

Related Posts

-

2025 Top Germany Made Bearings Review and Buying Guide

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

Top 10 Germany Made Bearings for Exceptional Performance and Reliability

-

Understanding the Factors Influencing Roller Bearing Prices: A Comprehensive Guide

-

Top 10 Machine Bearings: Best Types for Optimal Performance and Longevity

-

Exploring the Science Behind Miniature Bearings and Their Role in Modern Technology

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat