2025 How to Select the Best Machinery Bearings for Your Industrial Needs

When selecting the best machinery bearings for industrial needs, understanding the intricacies of this critical component is essential. According to Dr. John Smith, a renowned expert in the machinery bearing industry, "The right bearing choice can significantly impact the overall efficiency and longevity of your machinery." Bearings play a pivotal role in ensuring smooth operation, reducing friction, and enhancing performance across various applications.

As industries evolve and technological advancements reshape manufacturing processes, the importance of selecting high-quality machinery bearings becomes increasingly apparent. Factors such as load capacity, environmental conditions, and lubrication requirements must be carefully considered to optimize machinery performance. By analyzing these elements and staying informed about the latest innovations in the industry, engineers and procurement specialists can make educated decisions that will drive productivity and reduce operational costs. Understanding these aspects not only aids in preventing costly downtimes but also supports sustainable practices in industrial settings.

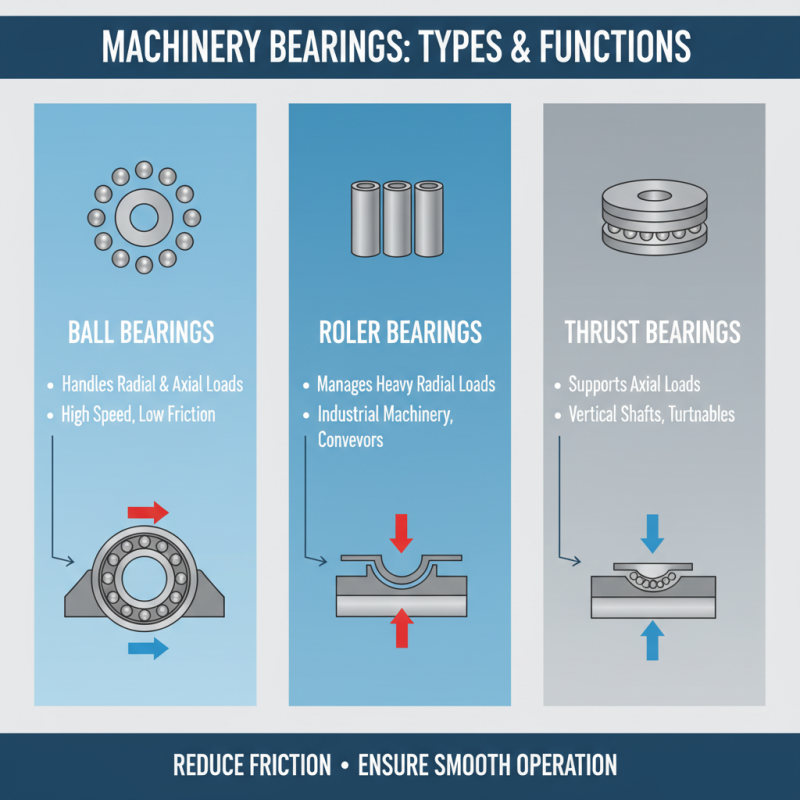

Understanding Machinery Bearings: Types and Functions

When selecting machinery bearings for industrial applications, it's essential to understand the various types and their functions. Bearings are critical components that facilitate the smooth operation of machinery by reducing friction between moving parts. The most common types include ball bearings, roller bearings, and thrust bearings, each designed for specific load types and conditions.

Ball bearings are versatile and can handle both radial and axial loads, making them ideal for high-speed applications. Roller bearings, on the other hand, can support heavier loads due to their larger contact area, which also allows for better stability. Thrust bearings are particularly suited for applications where axial loads are predominant, providing reliable support for rotating shafts.

**Tips**: When selecting bearings, consider factors such as load capacity, speed, and environmental conditions. Grease or lubricants may also play a vital role in the performance and longevity of bearings. Additionally, regular maintenance is crucial; a well-maintained bearing can significantly enhance the overall efficiency of machinery. Be sure to assess the specific requirements of your machinery to choose the most appropriate bearing type.

Key Factors in Selecting Machinery Bearings

When selecting machinery bearings for your industrial needs, several key factors must be carefully considered to ensure optimal performance and longevity. First and foremost, it is crucial to assess the operating conditions in which the bearings will function. This includes understanding the load capacity, speed requirements, and environmental factors such as temperature and humidity. These variables can significantly impact the type of bearing material and design that will best suit your application.

Another important aspect is the lubrication method. The right lubricant is essential for minimizing friction and wear, thus extending the lifespan of bearings. Depending on the machinery’s operation, you may choose between grease, oil, or even dry lubrication solutions. Adopting a proper maintenance schedule based on the selected lubrication will also ensure that the bearings remain in optimal condition over time.

**Tips:** When evaluating potential bearings, always consult the manufacturer’s specifications and guidelines for load ratings and limits. Conducting thorough research and possibly even prototyping with different bearings can save time and costs in the long run. Additionally, consider engaging with a bearing specialist who can provide tailored advice based on your specific industrial needs.

2025 How to Select the Best Machinery Bearings for Your Industrial Needs

This chart displays the key factors to consider while selecting machinery bearings, including Load Capacity, Durability, Cost, Lubrication, and Size Compatibility. Evaluating these factors can aid in optimizing performance and cost-effectiveness in industrial applications.

Material Considerations for Machinery Bearings

When selecting machinery bearings for industrial applications, material considerations play a pivotal role in ensuring optimal performance and longevity. The most common materials used for bearings include steel, ceramic, and polymer, each offering distinct advantages tailored to specific operational environments. Steel bearings, renowned for their strength and durability, are well-suited for high-load applications. However, they can be susceptible to corrosion, making proper sealing and lubrication essential to maintain functionality.

On the other hand, ceramic bearings present a lightweight alternative that excels in high-speed applications. Their resistance to wear and ability to operate in extreme temperatures make them ideal for niche scenarios, especially where traditional materials may fail. Meanwhile, polymer bearings offer significant benefits in corrosive environments, as they resist chemical attack and provide excellent noise dampening properties. The choice among these materials should consider factors such as load capacity, temperature ranges, environmental conditions, and required maintenance levels to ensure the selected bearings align with the specific demands of the machinery and the overall industrial application.

Evaluating Load Capacity and Durability

When selecting machinery bearings for industrial applications, evaluating load capacity and durability is paramount. According to a report by the International Organization for Standardization (ISO), the performance of bearings is primarily determined by their load capacity, which is influenced by material composition, design, and manufacturing processes. Particularly, rolling bearings typically have a dynamic load rating defined by their ability to support loads while maintaining operational efficiency, with common capacities ranging from 10 kN for smaller applications to over 2,000 kN for heavy-duty industrial machinery.

Durability is another critical factor in bearing selection. In a study by the American Society of Mechanical Engineers (ASME), it was highlighted that the fatigue life of bearings can significantly affect machinery downtime and overall maintenance costs. Analysis of bearing failure modes suggests that materials with higher tensile strength and superior surface finishes can enhance durability, reducing the likelihood of premature failure. Bearings made from advanced alloys or treated steels often exhibit a doubling of service life under comparable load conditions, making material choice a crucial consideration for sustaining operational reliability in industrial settings.

Best Practices for Maintenance and Replacement of Bearings

Maintenance and replacement of industrial bearings are crucial for ensuring the longevity and reliability of machinery. According to a report by the International Council on Mechanical Engineering, approximately 30% of mechanical failures in industrial settings are attributed to bearing issues. Regular maintenance practices, such as lubrication and alignment checks, can significantly reduce the risk of failure. For optimal performance, it's recommended to employ a maintenance schedule that aligns with the manufacturer's specifications, which often outlines specific intervals based on operating conditions.

Moreover, understanding the signs of bearing wear is vital for timely replacement. Common indicators include abnormal noise, vibration, and temperature increases. The American Society of Mechanical Engineers (ASME) highlights that premature bearing failure can lead to unscheduled downtimes, costing industries millions annually. Implementing vibration analysis and thermal imaging can provide valuable insights into bearing health, allowing for proactive maintenance strategies. By adhering to these best practices, industries can minimize operational disruptions and improve overall equipment efficiency.

Related Posts

-

Top 10 Machine Bearings: Best Types for Optimal Performance and Longevity

-

Understanding the Factors Influencing Roller Bearing Prices: A Comprehensive Guide

-

Top 10 Germany Made Bearings for Exceptional Performance and Reliability

-

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

-

Top Linqing Bearing Applications and Benefits for Industrial Uses

-

How to Choose the Right Self Aligning Ball Bearing for Your Application

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat