Exploring the Science Behind Miniature Bearings and Their Role in Modern Technology

The significance of miniature bearings in modern technology cannot be overstated, as they are pivotal components in a variety of industries, including aerospace, electronics, and medical devices. According to a recent market research report by Grand View Research, the global miniature bearings market is projected to reach USD 1.4 billion by 2025, driven by increasing demand for precision machinery and high-performance equipment. These small yet incredibly efficient components help reduce friction and wear in applications ranging from miniature motors to robotics, which underscores their role in enhancing energy efficiency and performance reliability. As technology advances, the need for more compact and lightweight designs amplifies the demand for miniature bearings, making them an essential focus for innovation in engineering and manufacturing processes. This article will delve into the science behind these crucial components, elucidating their functionality and impact on contemporary technologies.

Understanding the Basics of Miniature Bearings and Their Construction

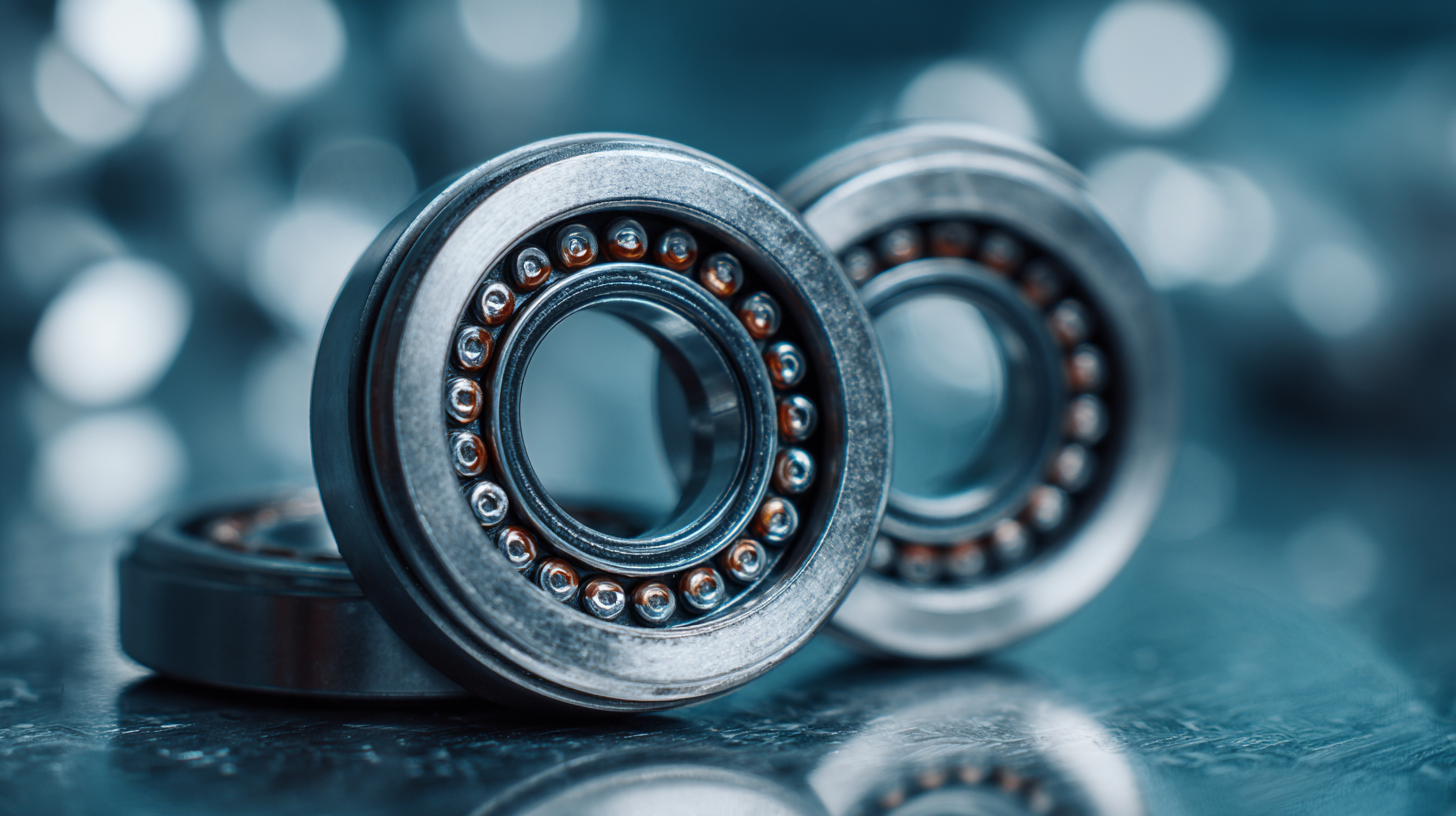

Miniature bearings are essential components in various modern technologies, enabling smooth movement and high precision in applications ranging from electronics to robotics. Understanding the basics of miniature bearings begins with their construction, which typically consists of an outer ring, an inner ring, a set of rolling elements, and often a cage to separate these elements. The smaller size of these bearings, generally under one inch in diameter, allows them to fit into compact spaces while maintaining functionality.

Miniature bearings are essential components in various modern technologies, enabling smooth movement and high precision in applications ranging from electronics to robotics. Understanding the basics of miniature bearings begins with their construction, which typically consists of an outer ring, an inner ring, a set of rolling elements, and often a cage to separate these elements. The smaller size of these bearings, generally under one inch in diameter, allows them to fit into compact spaces while maintaining functionality.

The materials used in the construction of miniature bearings are crucial for their performance and durability. High-quality steel or advanced ceramic materials are common, providing resistance to wear and corrosion. Additionally, the manufacturing process involves precision engineering techniques to ensure tight tolerances, which are vital for minimizing friction and enhancing the longevity of the bearing. Furthermore, the lubrication system, whether it be grease or oil, plays a significant role in optimizing the efficiency of miniature bearings by reducing heat generation during operation.

The Role of Miniature Bearings in Advancing Robotics and Automation

Miniature bearings have become a critical component in the fields of robotics and automation, playing an indispensable role in enhancing precision, efficiency, and overall performance. With the robotics market projected to grow at a CAGR of 26.7%, reaching nearly $390 billion by 2026, the demand for high-performance components like miniature bearings is surging (Source: Mordor Intelligence). These tiny yet powerful mechanisms are essential for achieving smooth operation in robotic joints and actuators, enabling sophisticated movements and dexterous handling of various tasks.

In automation, miniature bearings facilitate the integration of sub-millimeter scale robotics, which are increasingly employed in manufacturing processes. According to a report by MarketsandMarkets, the automation market alone is expected to grow from $200 billion in 2020 to $370 billion by 2026. The decreased friction and improved load capacity offered by miniature bearings make them ideal for applications requiring rapid movements and higher accuracy, such as conveyor systems and robotic assembly lines.

Tips: When selecting miniature bearings for your automation projects, consider factors such as load capacity, speed ratings, and environmental conditions. It's also beneficial to consult with manufacturers for insights on the best bearing types tailored to your application, ensuring optimal performance and longevity. Regular maintenance checks can also prevent downtime and enhance system reliability.

Applications of Miniature Bearings in Precision Instruments and Gadgets

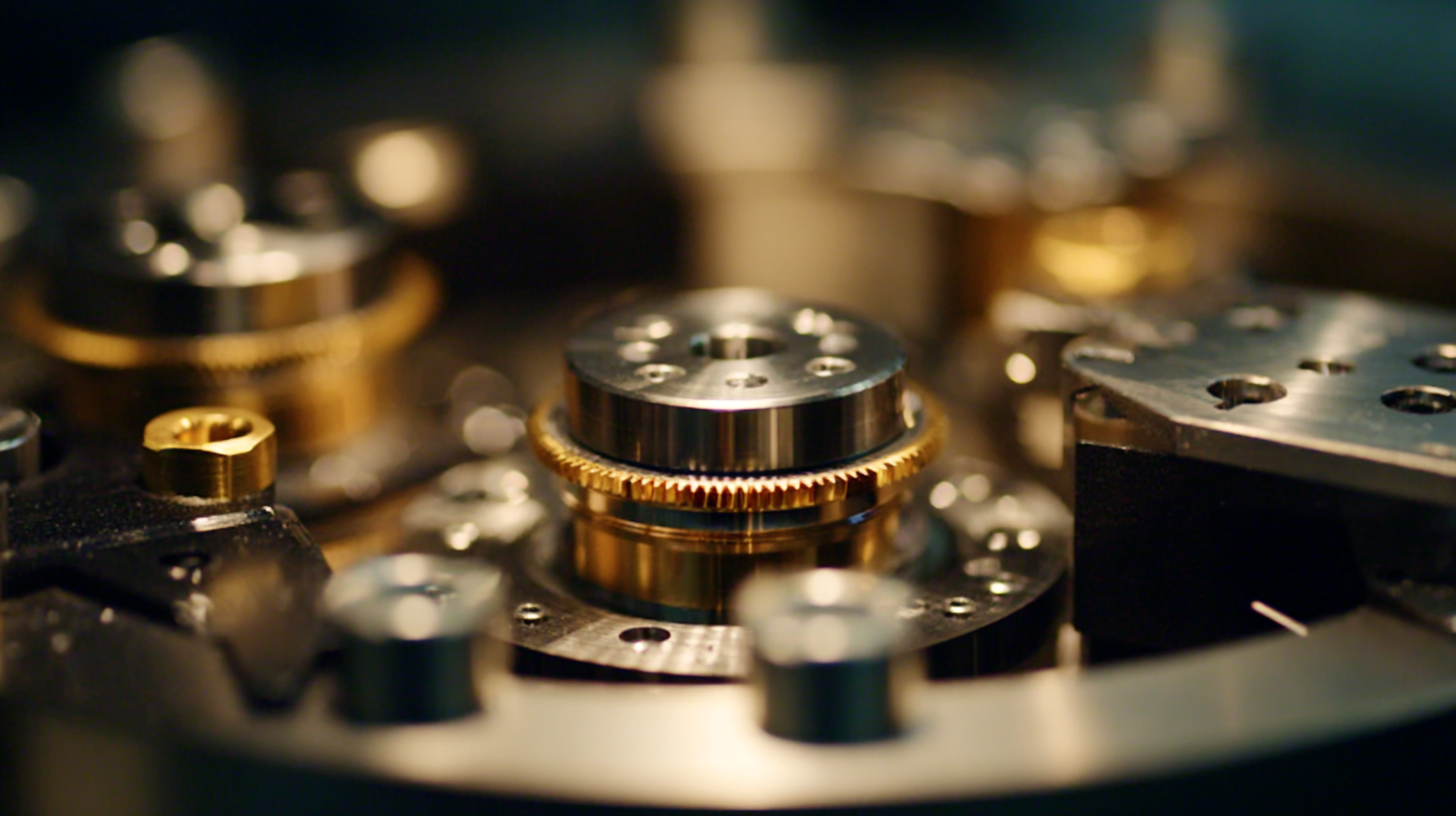

Miniature bearings play a crucial role in the functioning of precision instruments and gadgets, enabling smooth and efficient movement in compact designs. These tiny components are found in various applications, from high-end measuring devices like compasses to sophisticated consumer electronics. In modern technology, where space is often limited, the integration of miniature bearings ensures that instruments maintain their accuracy and reliability. They contribute significantly to the performance of devices, enhancing user experience in activities that demand precision, such as navigation and outdoor exploration.

The demand for advanced compact devices continues to grow, emphasizing the importance of high-quality miniature bearings. In many precision instruments, these bearings facilitate seamless operations, allowing users to trust their tools even in challenging environments. As technology evolves, manufacturers are focused on innovating the design and material of miniature bearings to meet the increasing requirements for durability and performance in various high-tech applications, thus ensuring that essential tools, like compasses, remain not just functional but superior in performance.

Challenges and Innovations in Miniature Bearing Technology

Miniature bearings are pivotal in various modern technological applications, yet they face significant challenges that demand innovative solutions. The increasing demand for compact and lightweight machinery, driven by advancements in electronics and aerospace, imposes strict performance and reliability requirements on miniature bearings. According to a recent market research report, the global miniature bearing market is expected to grow at a CAGR of 7.5% from 2021 to 2028, highlighting the significant investment in R&D to meet the evolving needs of industries including automotive, medical devices, and robotics.

One of the key challenges in the field is the trade-off between size and durability. As manufacturers strive to produce smaller bearings, they must also ensure that these components can withstand high loads and extreme environmental conditions. Innovations in materials science, such as the development of advanced composites and coatings, are paving the way for more resilient bearings. Additionally, the integration of smart technology into bearing design, allowing for real-time monitoring and predictive maintenance, represents a significant innovation that can enhance reliability and performance. Accenture's 2022 insights suggest that such advancements could lead to a 20% reduction in maintenance costs for industries reliant on miniature bearings, showcasing the critical role of innovation in overcoming existing challenges.

Future Trends in Miniature Bearings and Their Impact on Electronics

The miniature bearings industry is poised for significant developments in the coming years, especially as it plays an increasingly vital role in electronics. According to industry reports, the electronic-grade hydrofluoric acid market is projected to reach a value of $250.7 million by 2025, ballooning to an astonishing $8.35248 billion by 2033. This rapid growth not only indicates rising demand for high-purity materials essential for manufacturing advanced electronic components but also highlights the expanding market opportunities for miniature bearings, which are essential for the seamless operation of various compact electronic devices.

Furthermore, the electronic interconnect industry is navigating through macroeconomic fluctuations, tariff policy uncertainties, and supply chain adjustments as it approaches the second half of 2025. As these challenges mount, companies are increasingly seeking efficient and reliable miniature bearings to enhance the performance of their products. The ongoing digital transformation and the integration of technologies such as RFID also signify a shifting landscape in which miniature bearings will continue to be pivotal. By embracing these trends, the industry can significantly impact the evolution of modern technology, driving innovation and improving consumer experiences in electronics.

Exploring the Science Behind Miniature Bearings and Their Role in Modern Technology - Future Trends in Miniature Bearings and Their Impact on Electronics

| Dimension | Description | Applications | Future Trends |

|---|---|---|---|

| Load Capacity | Ability to support applied loads without failure. | Robotics, aerospace, and automotive applications. | Increasing miniaturization and strength of materials. |

| Friction | Resistance to motion between moving parts. | Hard disk drives, fans, and medical equipment. | Development of low-friction materials and coatings. |

| Temperature Tolerance | The range of temperatures within which the bearing operates effectively. | Electronics, food processing, and automotive engines. | Enhanced materials for extreme conditions. |

| Dimensions | Physical size of the bearing, precision engineered. | Smart devices, wearables, and drones. | Growing demand for compact and lightweight designs. |

| Lubrication | Use of grease or oil to minimize wear. | Agricultural machinery, robotics, and electronics. | Advancements in self-lubricating materials. |

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat