Understanding Linqing Bearings: Types, Applications and Benefits

Linqing Bearings are essential components in various machinery. They offer reliability and efficiency in numerous applications. Dr. Zhang Wei, a renowned expert in the bearing industry, once stated, "Linqing Bearings embody a blend of precision and durability." This statement captures the essence of what makes these bearings valuable.

These bearings come in many types. Each type serves unique purposes across different sectors. From automotive to aerospace, the applications are diverse. The benefits are significant, enhancing performance and reducing friction. This makes Linqing Bearings a popular choice among engineers and manufacturers alike.

Despite their advantages, there are areas for improvement. Quality control remains a concern for some manufacturers. The market needs to uphold higher standards to ensure longevity. While Linqing Bearings show great promise, continuous innovation is essential. The future of this industry depends on adapting to the evolving needs of technology.

Types of Linqing Bearings: An Overview of Key Varieties

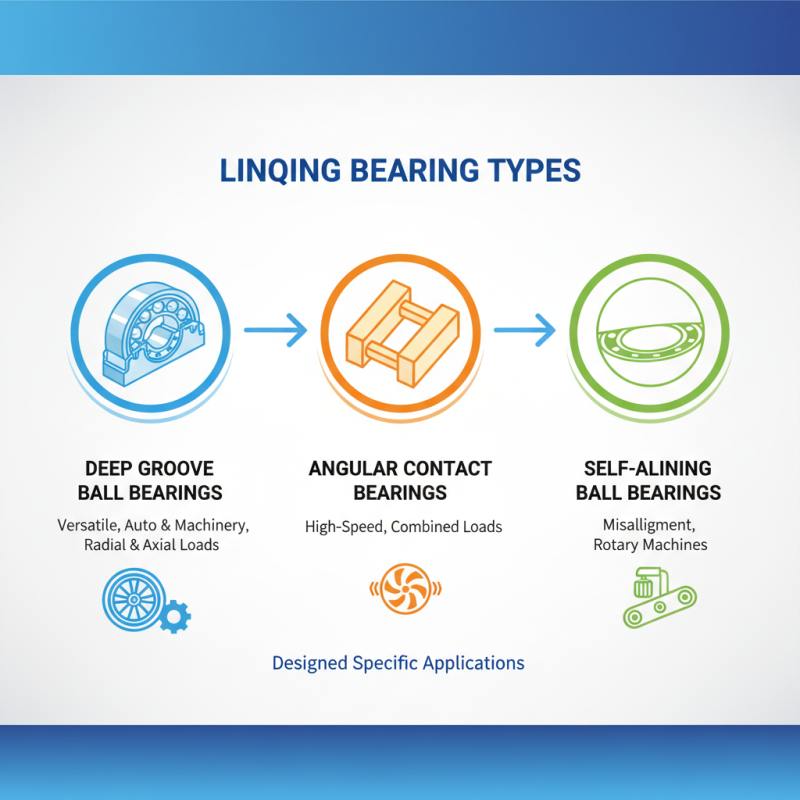

Linqing bearings come in several types, each designed for specific applications. The most common types include deep groove ball bearings, angular contact bearings, and self-aligning ball bearings. Deep groove ball bearings are versatile and widely used in automotive and machinery. They can handle radial and axial loads effectively. Angular contact bearings, on the other hand, are better suited for high-speed applications due to their ability to support combined loads.

Self-aligning ball bearings are ideal for situations where shaft misalignment may occur. They help maintain proper performance even when conditions are not perfect. Understanding these varieties is crucial for engineers and technicians. Choosing the right type can impact the efficiency of machinery. Running extensive tests can provide insights, but sometimes the wrong choice still happens.

Tips: Always consider the operating environment when selecting bearings. Look out for factors like temperature and load conditions. Testing prototypes is key to finding the best fit. It's essential to reflect on past choices to avoid similar mistakes in future projects. Remember, even minor details make a big difference.

Common Applications of Linqing Bearings Across Industries

Linqing bearings are widely used across various industries due to their reliability and efficiency. In manufacturing, these bearings support heavy machinery, aiding in smooth operations. For instance, reports show that around 20% of production downtime is linked to equipment failure. Quality bearings can mitigate such issues, showcasing their significant role.

In the automotive sector, Linqing bearings enhance vehicle performance. They help reduce friction, improving fuel efficiency. According to industry estimates, proper bearing selection can increase fuel economy by up to 5%. This small percentage translates to substantial savings for consumers and manufacturers alike. However, it's crucial to consider the environmental impact of materials used in bearings, such as steel and plastic.

The aerospace industry also benefits from Linqing bearings. They contribute to the reliability of various aircraft components. For example, reliable bearings can prevent catastrophic failures during flights. However, the high cost and complexity of sourcing quality bearings present challenges. Decision-makers must weigh benefits against costs carefully.

Benefits of Using Linqing Bearings in Mechanical Systems

Linqing bearings have become essential components in various mechanical systems. Their design offers several advantages, making them popular in numerous applications. One primary benefit is their ability to handle high loads. This characteristic enhances the performance of machinery, reducing the likelihood of failure under stress.

These bearings also provide low friction during operation. As a result, they help improve energy efficiency. When engines or machines run smoother, they consume less power. However, it is crucial to select the right type of bearing for specific applications. Using the wrong bearing can lead to excessive wear or malfunction, which could be costly.

Another benefit is their adaptability. Linqing bearings can be customized for unique needs, allowing for innovation in design. Still, it’s necessary to understand material choices and environmental factors. For instance, some materials might not withstand extreme temperatures. Evaluating these aspects can prevent future issues. Users should be mindful of these choices to ensure optimal operation.

Understanding Linqing Bearings: Types, Applications and Benefits

| Type of Bearing | Application | Benefits |

|---|---|---|

| Ball Bearing | Electric Motors, Fans | Low friction, High speed capability |

| Roller Bearing | Heavy Machinery, Conveyors | High load capacity, Durable |

| Thrust Bearing | Auto Transmissions, Marine Applications | Handles axial loads, Stability |

| Magnetic Bearing | High-speed Rotors, Turbines | No contact, Minimal wear |

| Fluid Bearing | High-load Applications, Precision Machinery | Low noise, Good vibration damping |

Factors to Consider When Choosing Linqing Bearings

When selecting Linqing bearings, several factors must be considered. The type of application plays a critical role. Different machines require distinct bearing types. For instance, industries like automotive and manufacturing may demand high load capacity bearings. According to industry reports, about 30% of machinery failures arise from improper bearing selection. This statistic highlights the importance of making informed choices.

Additionally, the operating conditions are essential. Temperature, humidity, and exposure to contaminants can affect the bearing's performance. Choosing a bearing with suitable materials can enhance durability. Bearings made from stainless steel tend to resist corrosion better than their counterparts. A study from the Bearing Industry Association shows that a 10% increase in operational temperature can reduce bearing life by up to 50%. This statistic draws attention to the need for careful consideration.

Cost is another crucial factor. While lower-priced bearings may seem attractive, they may compromise quality. Investing in a higher-grade bearing can yield long-term savings and lower maintenance costs. Reports indicate that poor-quality bearings lead to increased downtime, costing industries thousands of dollars annually. This reality urges buyers to weigh initial purchase costs against potential losses.

Understanding Linqing Bearings: Types and Applications

Maintenance Tips for Enhancing Linqing Bearings Performance

Linqing bearings are crucial for smooth operations in various machinery. To maintain their performance, regular maintenance is key. Proper care can extend the lifespan of these bearings significantly.

One important tip is to regularly clean the bearings. Dust and debris can accumulate, causing friction and wear. A simple routine of wiping down the bearings can help. Use a soft cloth to remove any dirt. It’s often overlooked, but this small effort can make a big difference.

Another recommendation is to check the lubrication levels frequently. Insufficient lubrication can lead to overheating and damage. Ideal lubrication prevents excess wear. Consider using a lubricant that suits the specific application. It’s easy to skip this step, but consistency is crucial for optimal performance.

Related Posts

-

2025 Top 10 Linqing Bearings: Discover the Leading Brands and Innovations

-

Top Linqing Bearing Applications and Benefits for Industrial Uses

-

Top 10 Machine Bearings: Best Types for Optimal Performance and Longevity

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

What is Japan Bearing and How It Impacts Industrial Applications

-

2025 How to Choose High Quality Bearings for Optimal Performance

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat