Top Linqing Bearing Applications and Benefits for Industrial Uses

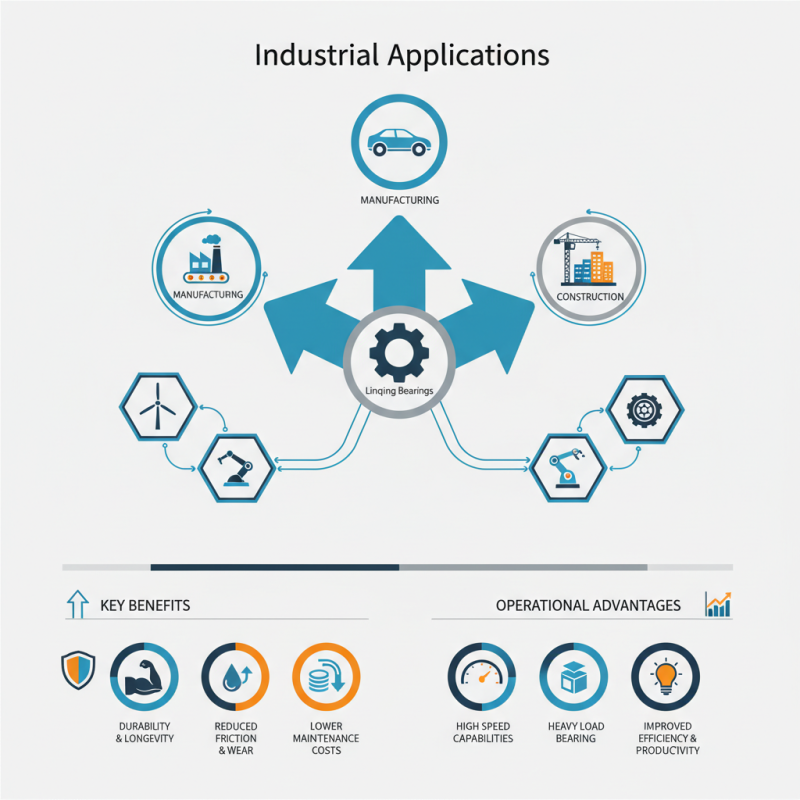

Linqing Bearing is a vital component in various industrial applications, renowned for its efficiency and reliability. As industries continue to evolve and modernize, the demand for high-quality bearing solutions has surged, making Linqing Bearing a go-to choice for many engineers and manufacturers. This introduction explores the top applications where Linqing Bearings excel, highlighting their crucial role in enhancing operational performance across diverse sectors such as manufacturing, automotive, and construction.

The benefits of Linqing Bearings extend beyond mere functionality; they are designed to withstand heavy loads and high speeds, ensuring durability and longevity in challenging operating conditions. Their superior design and material composition contribute to reduced friction and wear, ultimately leading to lower maintenance costs and increased productivity. In this discussion, we delve into how Linqing Bearings can meet the specific needs of various industries, providing insights into their application scenarios and the advantages they offer to improve overall equipment efficiency.

Top Applications of Linqing Bearings in Manufacturing Industries

Linqing bearings play a crucial role in various manufacturing industries due to their reliability and efficiency. One of the top applications of Linqing bearings is in the automotive sector, where they are essential components in engines, transmissions, and wheel assemblies. The precision and durability of these bearings ensure smooth operation, reduce friction, and enhance fuel efficiency, making them vital for modern vehicle performance. Additionally, their ability to withstand high temperatures and loads contributes to the longevity of automotive parts, thereby minimizing maintenance costs for manufacturers.

Another significant application of Linqing bearings is in the machinery and equipment sector. These bearings are widely used in industrial machines, including conveyors, pumps, and compressors, where they support rotational and linear movements. The incorporation of Linqing bearings in these machines helps to improve overall operational efficiency, reduce wear and tear, and increase productivity. Moreover, their versatility allows them to be adapted for various types of machinery, making them indispensable in manufacturing processes across different industries. By ensuring precision and reliability, Linqing bearings effectively enhance operational output and reduce downtime for manufacturers.

Key Benefits of Linqing Bearings for Machinery Performance

Linqing bearings are renowned for their superior performance and reliability in various industrial applications. One of the key benefits of using Linqing bearings lies in their ability to reduce friction and wear, enhancing machinery longevity. This not only maximizes operational efficiency but also minimizes the need for frequent maintenance, allowing manufacturers to focus on productivity. The precision engineering of Linqing bearings ensures consistent performance, even under heavy load conditions, making them ideal for high-speed applications.

Tips for selecting the right Linqing bearing include considering the operating environment, the load requirements, and the desired lifespan. Proper lubrication and regular inspections further enhance bearing performance, reducing downtime and extending the life of machinery. Additionally, opting for bearings with corrosion-resistant features can be beneficial in harsh environments, ensuring optimal functionality.

Another significant advantage of Linqing bearings is their noise reduction capability. By utilizing these bearings, industries can experience quieter operations, improving workplace conditions and reducing noise pollution. Effective vibration dampening also contributes to overall machinery stability, lowering the risk of failure and enhancing safety.

Comparative Analysis: Linqing Bearings vs. Traditional Bearings

When evaluating the performance of Linqing bearings in industrial applications, a comparative analysis with traditional bearings unveils significant advantages in efficiency and longevity. According to a recent industry report by the International Bearing Association, Linqing bearings exhibit a lower coefficient of friction, which can reduce energy consumption by up to 15% compared to conventional steel bearings. This decrease not only translates to cost savings but also contributes to improved operational sustainability, a critical factor for many industries today.

Moreover, Linqing bearings often feature advanced materials and innovative designs, enhancing their load-bearing capacity and resistance to wear. Data from the Global Bearing Market Report indicates that Linqing bearings have a lifespan increase of approximately 20% under similar working conditions when compared to their traditional counterparts. This extended durability means less frequent replacements and less downtime for maintenance, resulting in higher overall productivity for industrial operations. As industries increasingly prioritize efficiency and reliability, the shift towards Linqing bearings reflects a growing trend towards modernizing equipment with performance-driven solutions.

Top Linqing Bearing Applications and Benefits for Industrial Uses - Comparative Analysis: Linqing Bearings vs. Traditional Bearings

| Application Area | Linqing Bearings Advantages | Traditional Bearings Limitations |

|---|---|---|

| Automotive Industry | Higher load capacity and better heat resistance | Limited heat resistance |

| Aerospace Applications | Lightweight design and superior fatigue life | Heavier and less durable |

| Food Processing | Corrosion resistance and easy cleaning | Susceptible to rust and difficult to clean |

| Manufacturing Equipment | Lower friction and higher efficiency | Higher friction leading to energy loss |

| Agricultural Machinery | Enhanced durability in harsh conditions | Less durable and performance under stress |

Statistical Impact of Linqing Bearings on Operational Efficiency

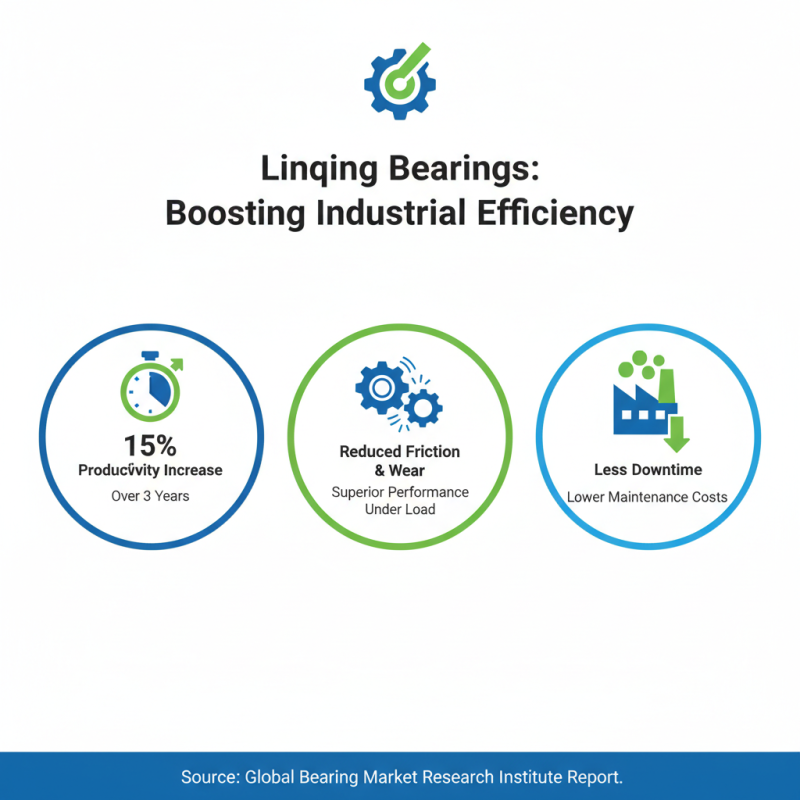

The significance of Linqing bearings in enhancing operational efficiency in industrial settings cannot be overstated. According to a recent report by the Global Bearing Market Research Institute, industries utilizing high-quality bearing solutions, such as those produced in Linqing, experienced an average productivity increase of 15% over three years. This boost is attributed to the bearings' superior performance under load, which minimizes friction and wear, leading to less downtime and lower maintenance costs.

Moreover, the reliability of Linqing bearings directly contributes to the longevity of machinery. A study published by the International Journal of Mechanical Engineering found that organizations employing advanced bearing technology reported a decrease in machinery failure rates by approximately 25%. This reduction is particularly critical in sectors such as manufacturing and logistics, where unanticipated breakdowns can result in significant operational disruptions and financial losses. As companies increasingly adopt Linqing bearings, they leverage these statistical advantages, translating into smoother operations and a more robust bottom line.

Future Trends in Linqing Bearing Technology for Industrial Use

As industries continue to evolve, Linqing bearing technology is on the cusp of significant advancements that promise to enhance efficiency, reliability, and performance in various applications. One prominent trend is the integration of smart technology into bearing systems. Smart bearings equipped with sensors will facilitate real-time monitoring, providing crucial data regarding temperature, vibration, and load conditions. This information enables predictive maintenance, reducing downtime, and minimizing maintenance costs, which is essential for industries reliant on continuous operation.

Another emerging trend is the shift towards the use of advanced materials in bearing manufacturing. The incorporation of composite materials and high-performance polymers will not only reduce weight but also increase the fatigue resistance and lifespan of bearings. This shift will enable industries, particularly those in high-speed and high-load sectors, to achieve better operational performance while also maximizing energy efficiency. Additionally, sustainable practices are increasingly influencing development, with a focus on creating environmentally friendly bearings that reduce environmental impacts during production and throughout their lifecycle, thus meeting growing regulatory and market demands for sustainability in industrial operations.

Related Posts

-

2025 Top 10 Linqing Bearings: Discover the Leading Brands and Innovations

-

Top 10 Tapered Roller Bearings for Optimal Performance and Longevity

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

Top 10 Germany Made Bearings for Exceptional Performance and Reliability

-

2025 Top 10 Mounted Bearing Innovations You Need to Know

-

2025 Top Germany Made Bearings Review and Buying Guide

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat