Why Japan Bearings Are Essential for Industry and How to Choose the Best Ones

In the realm of modern industry, the significance of high-quality components cannot be overstated, and Japan Bearings stand out as a benchmark for excellence. Renowned for their precision engineering and durability, these bearings play a critical role in ensuring the smooth operation of machinery across various sectors, including automotive, aerospace, and manufacturing. The reliability and performance of Japan Bearings contribute substantially to reducing downtime and enhancing productivity, making them an indispensable element in today's competitive industrial landscape.

Choosing the right bearings is crucial for optimizing performance and efficiency. With a plethora of options available, understanding the key features and specifications of Japan Bearings is essential. Factors such as load capacity, material composition, and design variations influence how bearings function under specific conditions. Hence, it's vital for industry professionals to equip themselves with the knowledge necessary to navigate the choices and select the best options that align with their unique requirements. By focusing on Japan Bearing technology, businesses can unlock new levels of performance and reliability, transforming their operational effectiveness in a fast-evolving marketplace.

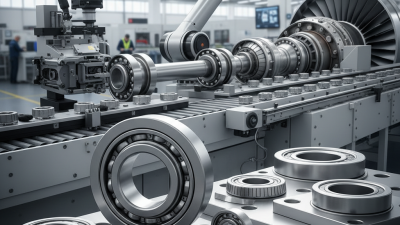

The Importance of Bearings in Industry

Bearings play a crucial role in the operation of various industrial machinery, as they facilitate smooth movement and reduce friction between moving parts. In industries ranging from manufacturing to automotive, bearings help ensure that equipment operates efficiently and reliably. By minimizing wear and tear, bearings enhance the lifespan of machines, thus contributing to productivity and cost savings. The importance of bearings cannot be overstated; their proper functioning directly influences overall operational performance, making them vital components in any industrial setup.

When choosing the best bearings for specific applications, several factors must be considered. Load capacity, speed ratings, and environmental conditions are essential parameters that determine which type of bearing will perform best in a given context. Additionally, the lubrication requirements and material compatibility should align with the operational demands. Understanding these factors allows industries to select bearings that not only meet their performance needs but also optimize maintenance schedules and minimize downtime. In sum, selecting the right bearings is integral to the operational success of any industrial process, highlighting their significance within the sector.

Overview of Japanese Bearing Manufacturing Standards

Japan has earned a reputation for its stringent bearing manufacturing standards, which are critical in ensuring high performance and reliability across various industries. These standards are guided by a combination of precision engineering, advanced material selection, and rigorous testing protocols. Japanese bearing manufacturers adhere to meticulous guidelines that not only meet but often exceed international norms. This commitment to quality results in bearings that provide superior durability, reduced friction, and enhanced operational efficiency, making them a preferred choice for applications that demand exceptional reliability.

In selecting the right bearings, it is imperative to consider factors such as load capacity, speed ratings, and environmental conditions. The Japanese approach emphasizes a thorough understanding of the application requirements and stresses the importance of selecting bearings that can withstand specific operational stresses. Additionally, manufacturers often provide detailed specifications that ensure the bearings can perform optimally under various conditions. By following these robust standards and guidelines, industries can ensure they choose the best bearings that meet operational demands while minimizing downtime and maintenance costs.

Key Features of High-Quality Japanese Bearings

When selecting high-quality Japanese bearings for industrial applications, several key features should be prioritized to ensure optimum performance and longevity. Japanese bearings are renowned for their precision engineering, which significantly reduces the friction and wear during operation. This leads to increased efficiency and reliability in machinery, making them a staple in various industries such as automotive, aerospace, and robotics. According to a recent report by the Japan Bearing Manufacturer’s Association, high-quality bearings can enhance machine reliability by up to 25%, ultimately lowering total operational costs.

One of the essential characteristics to consider is the material composition. High-quality Japanese bearings are typically manufactured from advanced materials like stainless steel or specialized alloys that withstand extreme conditions. Furthermore, attention should be paid to the bearing's design, such as raceway geometry and lubrication methods, which contribute to their performance under load. A study by the International Journal of Mechanical Engineering found that bearings designed with optimized geometries lead to a 15% improvement in load capacity, a critical factor for industrial applications.

Tips: When choosing Japanese bearings, always assess the load ratings and speed capabilities provided in the technical specifications. Additionally, ensure compliance with international quality standards, such as ISO 9001, to guarantee reliability. Lastly, consider any environmental factors that might affect bearing performance in your specific application, such as temperature variations and exposure to contaminants.

Factors to Consider When Choosing Bearings

When selecting bearings for industrial applications, several key factors must be considered to ensure optimal performance and longevity. First, the load capacity of the bearing is crucial. According to a report from the International Journal of Engineering and Advanced Technology, the load capacity can significantly influence the operational efficiency of machinery, with improperly selected bearings leading to increased downtime and repair costs. Experts suggest that a thorough understanding of the specific load requirements—static versus dynamic—is essential for reliable performance in the intended application.

Material selection is another critical aspect when choosing bearings. The type of material can impact the bearing's resistance to wear and environmental factors. Common materials include stainless steel and ceramic, each offering unique advantages in terms of temperature resistance and corrosion resistance. A study by the American Society of Mechanical Engineers highlights that choosing the right material can enhance the lifespan of bearings by 30-50%, depending on the operational conditions.

**Tips:** Always assess the operational environment before selecting bearings; for example, in corrosive environments, consider bearings with higher resistance to chemical exposure. Additionally, consult reliability analysis reports to understand how different bearing types perform under similar conditions to ensure you make an informed decision tailored to your specific industrial needs.

Bearings Selection Factors

Comparative Analysis of Japanese Bearings vs. Global Options

When evaluating the performance of bearings, the differences between Japanese options and those from other global manufacturers become evident. Japanese bearings are renowned for their precision engineering, reliability, and long service life. One key factor contributing to this reputation is Japan's commitment to advanced manufacturing technologies and quality control processes.

These bearings often utilize superior materials and innovative designs, resulting in products that perform exceptionally well under various industrial conditions. Additionally, their ability to withstand extreme temperatures and loads makes them a preferred choice for critical applications in automotive, aerospace, and machinery sectors.

In contrast, bearings from other regions may not always meet the same rigorous standards. While some global alternatives can offer cost advantages, they might compromise on quality or consistency. Manufacturers outside Japan may focus on producing a broader range of products at lower prices, potentially leading to increased wear and early failure in high-demand settings.

Consequently, when selecting bearings, it's essential for industries to weigh the long-term benefits of investing in Japanese bearings against the initial savings of cheaper global options. This analysis underscores the importance of the intended application and operational requirements, guiding users toward the best choice for their specific needs.

Related Posts

-

2025 How to Choose High Quality Bearings for Optimal Performance

-

How to Choose the Right Self Aligning Ball Bearing for Your Application

-

Top 10 Germany Made Bearings for Exceptional Performance and Reliability

-

Top 10 Machine Bearings: Best Types for Optimal Performance and Longevity

-

Top 2025 Guide to Flange Bearings Applications and Benefits Explained

-

2025 How to Select the Best Machinery Bearings for Your Industrial Needs

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat