What is Japan Bearing and How It Impacts Industrial Applications

Japan Bearing plays a pivotal role in the global industrial landscape, contributing significantly to the efficiency and effectiveness of various manufacturing processes. According to a recent report by the Japan Bearing Industry Association, the bearing market in Japan is projected to reach a value of $20 billion by 2025, driven by increasing demand from sectors such as automotive, aerospace, and robotics. As industries strive for enhanced performance and sustainability, bearings emerge as critical components that facilitate smoother operations and reduce energy consumption.

Experts in the field emphasize the importance of Japan Bearing technology in shaping industrial applications. Dr. Hiroshi Tanaka, a renowned bearing specialist, states, “The innovation and precision found in Japan Bearing technology not only enhance machine lifespan but also optimize overall productivity.” This insight reflects the broader impacts of Japanese bearing design, where advancements in materials and engineering continue to lead the world. As industries evolve, leveraging the capabilities of Japan Bearings remains essential for maintaining competitive advantages across various sectors. Indeed, their influence extends beyond simple mechanical function to become integral to the future of industrial efficiency.

What is Japan Bearing?

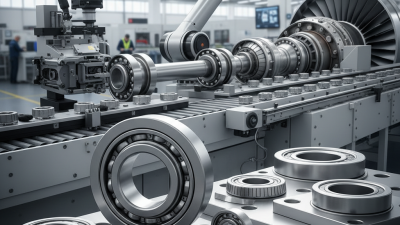

Japan bearing refers to high-quality bearings manufactured in Japan, renowned for their precision engineering and durability. These bearings are utilized across various industrial applications, including automotive, aerospace, and machinery manufacturing. According to a report by Research and Markets, the global bearing market was valued at approximately $95 billion in 2022 and is projected to grow significantly, with Japan holding a substantial share due to its advanced manufacturing techniques and stringent quality controls.

The unique characteristics of Japan bearings make them a preferred choice in critical applications where reliability and performance are paramount. For instance, the Japan Society of Mechanical Engineers notes that these bearings provide lower friction, higher efficiency, and longer service life compared to their counterparts. This results in reduced maintenance costs and improved operational efficiency, which is essential for industries that rely on high-speed and high-load machinery.

Additionally, Japan's focus on innovation and technology contributes to the continuous development of bearing materials and designs. Industry analysis by MarketWatch indicates a rising demand for high-performance bearings, particularly in electric vehicles and renewable energy sectors, where Japan bearings are leading the charge in meeting the evolving needs of modern industrial applications.

Types of Japan Bearings Used in Industries

Japan bearings play a crucial role in various industrial applications due to their precision engineering and durability. Among the different types of Japan bearings used in industries, ball bearings and roller bearings are the most prominent. According to a report by Research and Markets, the global market for industrial bearings is expected to grow from USD 90 billion in 2020 to over USD 130 billion by 2025, with a significant share contributed by Japanese manufacturers known for their advanced technology and quality standards.

Ball bearings are widely used in motors, pumps, and machinery to reduce friction between moving parts, enhance efficiency, and prolong equipment lifespan. They typically consist of rolling elements that provide lower friction than sliding bearings, making them ideal for high-speed applications. On the other hand, roller bearings, which come in various forms such as cylindrical, spherical, and tapered, primarily support heavier loads and are commonly found in automotive and construction machinery. The bearings market analysis indicates that the demand for roller bearings is expected to rise alongside the growing trend of automation and heavy machinery use in various sectors.

The impact of these bearings on industrial efficiency cannot be understated. They contribute to lower operational costs by minimizing energy loss and wear on equipment. Additionally, Japan's stringent quality control measures and advanced manufacturing processes ensure that these bearings offer exceptional performance and reliability, which are essential for sustaining productivity in a competitive industrial landscape. With the ongoing advancements in bearing technologies, including the use of advanced materials and smart bearings, the future of industrial applications continues to rely heavily on the innovations pioneered in Japan.

Types of Japan Bearings and Their Industrial Impact

This bar chart illustrates the distribution of different types of Japan bearings used in various industrial applications. The data represents the percentage usage of each type, highlighting the significance of Ball Bearings, Roller Bearings, and others in the industrial sector.

Key Characteristics and Benefits of Japan Bearings

Japan bearings are renowned for their superior quality and precision, making them a crucial component in various industrial applications. One of the key characteristics of Japan bearings is their exceptional manufacturing standards, which adhere to rigorous quality control processes. According to a report by the International Federation of Robotics, Japan remains among the top countries in robotics and automation technologies, which further enhances the demand for high-performance bearings in manufacturing sectors. These bearings often exhibit reduced friction, minimal wear, and extended operational life, contributing to improved efficiency in machinery and equipment.

In addition to their durability, Japan bearings offer significant benefits over lower-quality alternatives. The precision engineering involved in their production allows for tighter tolerances, reducing vibration and noise in machinery. A report from TechNavio indicated that the global bearing market is expected to grow at a CAGR of approximately 5% through 2025, driven by the increasing demand for industrial automation and electric vehicles, where high-quality bearings play a vital role. Furthermore, the lubrication properties of Japan bearings can lead to lower maintenance costs and longer intervals between service, making them an economically viable choice for industries aiming to enhance their productivity and reduce operational costs.

What is Japan Bearing and How It Impacts Industrial Applications - Key Characteristics and Benefits of Japan Bearings

| Characteristic | Description | Benefit |

|---|---|---|

| High Precision | Japan bearings are manufactured with strict quality control and precision engineering. | Enables smoother operation and reduces wear in machinery. |

| Durability | These bearings are designed to withstand heavy loads and harsh operating conditions. | Longer service life reduces maintenance costs and downtime. |

| Low Friction | Utilization of advanced materials and lubricants minimizes friction. | Improves energy efficiency and operational effectiveness. |

| Temperature Resistance | Designed to operate at high and low temperatures without failure. | Ensures reliable performance across varied conditions. |

| Wide Range of Applications | Suitable for automotive, aerospace, and industrial machinery uses. | Versatility allows for integration in various engineering solutions. |

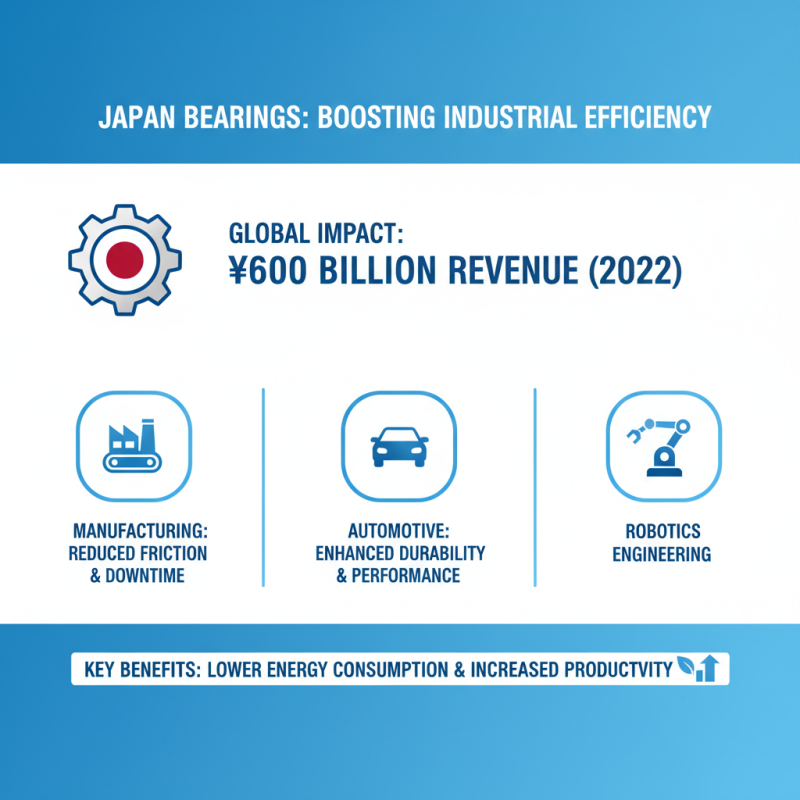

Impact of Japan Bearings on Industrial Efficiency

Japan bearings play a critical role in enhancing industrial efficiency across various sectors, including manufacturing, automotive, and robotics. According to a report from the Japan Bearing Industry Association, the country's bearing industry accounted for approximately ¥600 billion in revenue in 2022, demonstrating its significant contribution to global markets. Japan's engineering expertise has led to the development of high-precision bearings that reduce friction, increase durability, and improve overall machine performance. These advancements result in lower energy consumption and minimized downtime, thereby enhancing production efficiency.

The impact of Japanese bearings is most evident in their application within automated machinery and heavy equipment. A study published in the International Journal of Engineering Research indicated that the integration of high-quality bearings can boost operational efficiency by up to 30%. Additionally, the reduction in vibration and heat generation in machinery equipped with Japan bearings leads to extended service life and reduced maintenance costs. As industries strive to achieve greater throughput and cost-effectiveness, the advantages provided by Japanese bearing technology become increasingly vital in maintaining a competitive edge in the global marketplace.

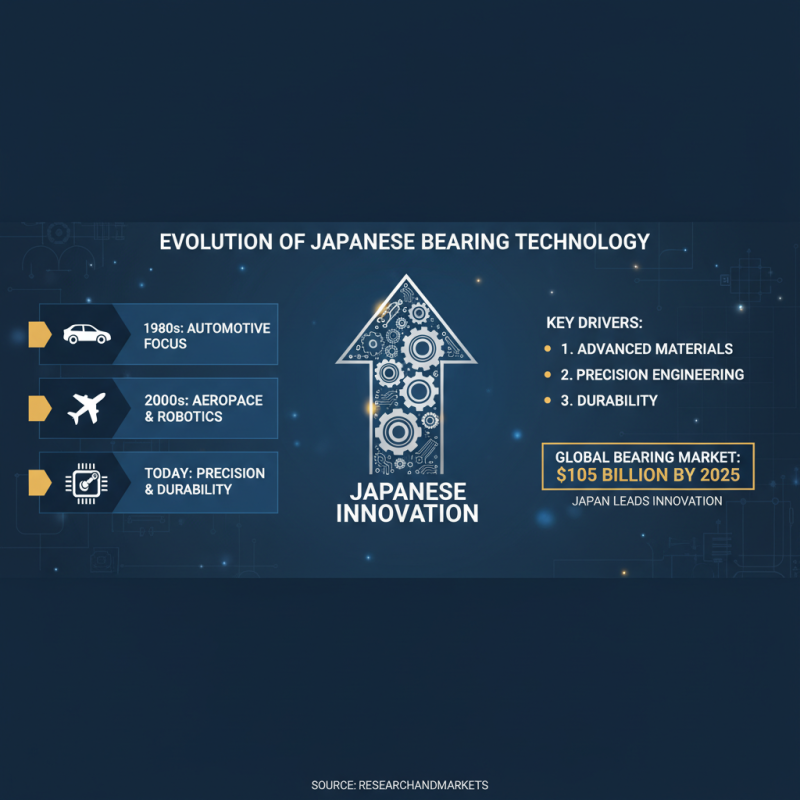

Future Trends in Japan Bearing Technologies

The evolution of bearing technologies in Japan is closely linked to the advancements in various industrial applications. Japanese manufacturers are at the forefront of developing high-performance bearings designed for specific needs in diverse sectors, including automotive, aerospace, and robotics. As industries explore greater efficiencies, the emphasis on materials and design is becoming critical. According to a report by ResearchAndMarkets, the global bearing market is projected to reach USD 105 billion by 2025, with Japan leading innovations driven by a focus on precision engineering and durability in bearing manufacturing.

Future trends in Japanese bearing technologies include the integration of smart bearings equipped with sensors that monitor performance in real-time, enhancing predictive maintenance capabilities. This shift towards IoT-enabled solutions is expected to revolutionize how industrial equipment is maintained, reducing downtime and improving efficiency. Furthermore, the adoption of advanced materials such as ceramics and polymers is on the rise, promising lighter and stronger bearings that meet the increasing demands of high-speed and high-load applications. The Japan Bearing Industrial Association has indicated that these innovations could lead to a reduction of up to 30% in energy consumption across various applications, positioning Japan as a leader in sustainable industrial practices.

Related Posts

-

Why Japan Bearings Are Essential for Industry and How to Choose the Best Ones

-

2025 How to Select the Best Machinery Bearings for Your Industrial Needs

-

How to Choose the Right Fan Bearing for Optimal Performance and Longevity

-

2025 Top Germany Made Bearings Review and Buying Guide

-

Top 2025 Guide to Flange Bearings Applications and Benefits Explained

-

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat