Top 2025 Guide to Flange Bearings Applications and Benefits Explained

In the evolving landscape of industrial applications, flange bearings have emerged as critical components in various mechanical systems. According to a recent market analysis by the Global Bearing Market Report, the flange bearing segment is projected to witness a compound annual growth rate (CAGR) of 4.5% from 2023 to 2028, demonstrating significant adoption across multiple sectors including automotive, aerospace, and manufacturing. These bearings are specifically designed for applications where space constraints and load requirements necessitate robust yet compact solutions.

Flange bearings offer several distinct advantages that make them essential in numerous applications. They facilitate smoother operations by minimizing friction and wear, thereby enhancing equipment lifespan and reducing maintenance costs. Moreover, their ease of installation allows for rapid integration into existing systems, which is invaluable in fast-paced industrial environments. A report by Allied Market Research indicates that the increasing demand for automation and high-performance machinery will further drive the need for efficient flange bearings, highlighting their vital role in innovation and productivity enhancements across industries.

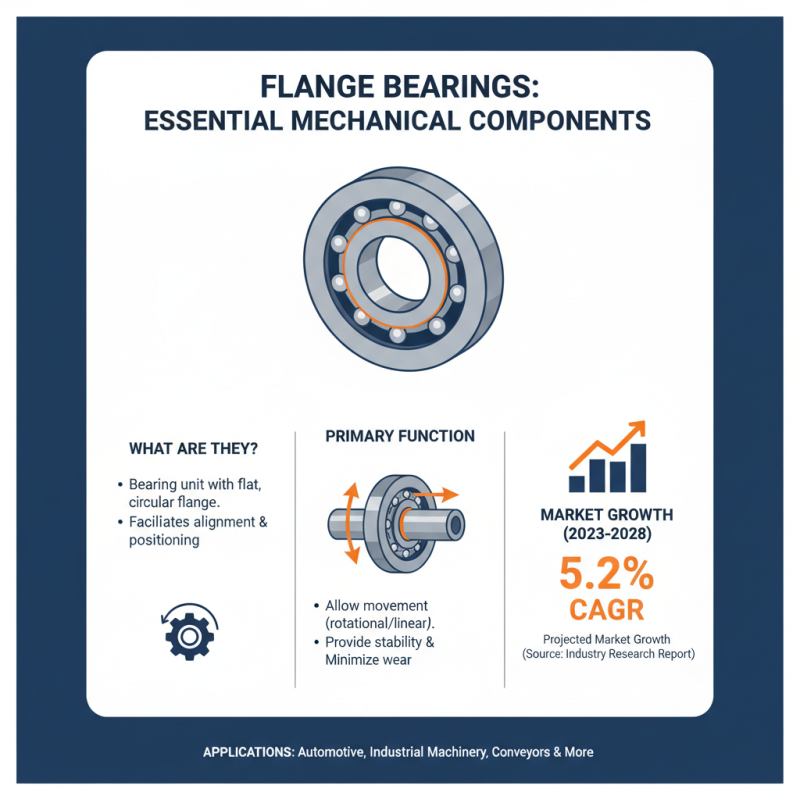

Overview of Flange Bearings: Definition and Functionality

Flange bearings are crucial components in various mechanical systems, providing support and reducing friction between moving parts. Defined as bearing units that feature a flat, circular flange on one or both ends, these bearings facilitate alignment and positioning in applications ranging from automotive to industrial machinery. Their primary function is to allow rotational or linear movement while maintaining stability and minimizing wear. According to a recent market report by Industry Research, the flange bearings market is projected to grow at a CAGR of 5.2% from 2023 to 2028, highlighting their increasing significance in modern engineering applications.

One of the greatest advantages of flange bearings is their versatility. They can be easily integrated into a variety of systems due to their simple design and adaptability to different mounting configurations. For instance, they are commonly utilized in conveyor systems, where they support rollers that require consistent and reliable motion. A study by the Bearing Market Analysis Group indicates that nearly 45% of industrial users have reported improved efficiency and reduced maintenance costs through the implementation of flange bearings in machinery.

Tips: When selecting flange bearings for your application, consider the load capacity and environmental factors such as temperature and exposure to contaminants. Ensuring proper alignment during installation can drastically reduce wear and enhance the lifespan of the bearings. Always refer to manufacturer specifications and best practices to optimize performance and reliability in your specific application.

Common Applications of Flange Bearings in Various Industries

Flange bearings are integral components in various industrial applications, offering stability and efficiency across a multitude of environments. One of the most common uses of flange bearings is in conveyor systems, where they provide smooth movement and precise alignment for conveyor belts. Their robust design ensures that they can withstand heavy loads while minimizing friction, making them ideal for transporting materials in manufacturing and logistics sectors. The ease of installation due to their flanged design further enhances their usability in these applications.

In the automotive industry, flange bearings play a critical role in assembly lines and powertrain systems. They support rotating shafts and maintain alignment, ensuring that various components function smoothly together. This is particularly important in electric vehicles, where the efficiency and reliability of moving parts are paramount for performance. Additionally, flange bearings are used in household appliances, such as washing machines and dishwashers, where they help reduce noise and vibration while enhancing overall durability. Their versatility across different applications underlines their importance in ensuring operational efficiency across various industries.

Top 2025 Guide to Flange Bearings Applications and Benefits Explained

| Industry | Common Applications | Benefits |

|---|---|---|

| Automotive | Wheel assemblies, steering systems | Enhanced durability, reduced friction |

| Aerospace | Landing gear systems, control surfaces | Lightweight solutions, high strength |

| Manufacturing | Conveyor systems, machinery support | Improved performance, easier maintenance |

| Construction | Heavy equipment, cranes | Increased load capacity, reliability |

| Robotics | Joint mechanisms, linear actuators | Precision movement, compact design |

Key Benefits of Using Flange Bearings in Machinery

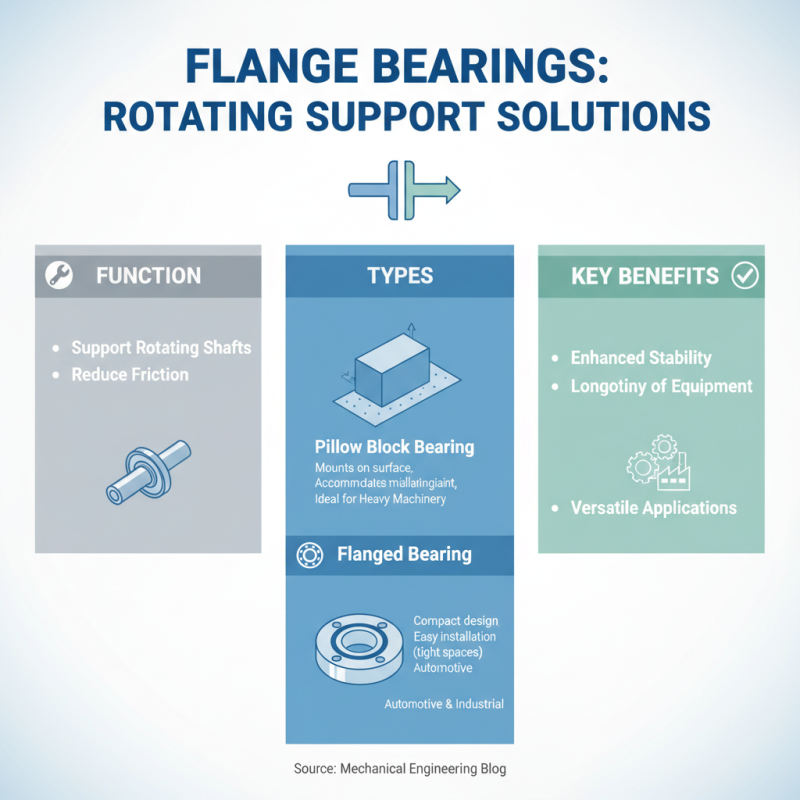

Flange bearings are integral components in various machinery, offering a range of benefits that enhance performance and efficiency. One of the primary advantages of using flange bearings is their ability to support high radial loads while maintaining precise alignment. This stability is crucial in applications where equipment experiences frequent vibrations or heavy loads. The design of flange bearings typically allows for straightforward installation, enabling quicker assembly and disassembly, which is beneficial for maintenance procedures.

Another key benefit of flange bearings is their versatility in accommodating different shaft sizes and configurations. This adaptability makes them suitable for a wide range of applications, from industrial machines to automotive components. Additionally, flange bearings often provide excellent durability due to their robust construction, which helps to minimize wear and extend the lifespan of the machinery. The reduced friction and heat generation associated with high-quality flange bearings also contribute to the overall efficiency of the system, leading to lower energy consumption and improved operational performance.

Types of Flange Bearings and Their Distinct Features

Flange bearings are essential components in various mechanical applications, known for their ability to support rotating shafts and reduce friction. There are several types of flange bearings, each tailored for specific functions and environments. For instance, the pillow block bearing is designed to mount on a surface and accommodate misalignment, making it ideal for heavy machinery. Meanwhile, the flanged bearing offers a compact design, allowing for easy installation in tight spaces, which is beneficial in automotive and industrial settings.

It is essential to consider the distinct features of these bearings when selecting the appropriate type for your project. The material used for each flange bearing can significantly affect its performance. For high-load applications, choosing bearings made from high-strength materials, such as steel or high-grade plastics, can enhance durability and lifespan. Additionally, some flange bearings come with seals or shields, which offer added protection against contaminants, making them well-suited for outdoor use or environments with dust and moisture.

Tips: When selecting flange bearings, always assess the load requirements and operational environment; this can help in choosing the right type and extending the longevity of your machinery. Regular maintenance, including lubrication and inspection for wear, is crucial to ensure optimal performance and prevent unexpected failures.

Maintenance Tips for Enhancing Flange Bearings Longevity

Maintaining flange bearings properly is crucial for ensuring their longevity and optimal performance in various industrial applications. According to a report by the American Society of Mechanical Engineers, improper maintenance can lead to a 30% reduction in bearing life, resulting in costly downtimes and repairs. Regular inspection and adherence to manufacturer guidelines can significantly enhance the lifespan of these critical components. It's essential to keep bearings free from contaminants and ensure they are adequately lubricated to minimize wear and tear.

One effective maintenance tip is to perform routine vibration analysis, which can detect early signs of fatigue and misalignment. The International Organization for Standardization suggests that implementing a predictive maintenance program can extend the service life of flange bearings by up to 40%. Additionally, maintaining a consistent lubrication schedule with the appropriate type of grease not only helps to reduce friction but also protects against moisture and corrosion, extending the overall lifespan of the bearings. Regularly monitoring operating temperatures is also beneficial, as it can indicate potential issues before they escalate into significant failures, ensuring smooth operations and preventing unnecessary interruptions.

Flange Bearings Applications and Benefits Overview

This bar chart illustrates the distribution of flange bearings applications across various industries. Automotive sector leads with a significant share, followed by aerospace and machinery, emphasizing their critical role in enhancing efficiency and performance in these fields.

Related Posts

-

Top 10 Germany Made Bearings for Exceptional Performance and Reliability

-

Exploring the Science Behind Miniature Bearings and Their Role in Modern Technology

-

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

-

Top 10 China Bearing Factory Insights for Quality and Production Efficiency

-

What is the Average Roller Bearing Price and Factors Affecting It

-

2025 Top 10 Linqing Bearings: Discover the Leading Brands and Innovations

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat