Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

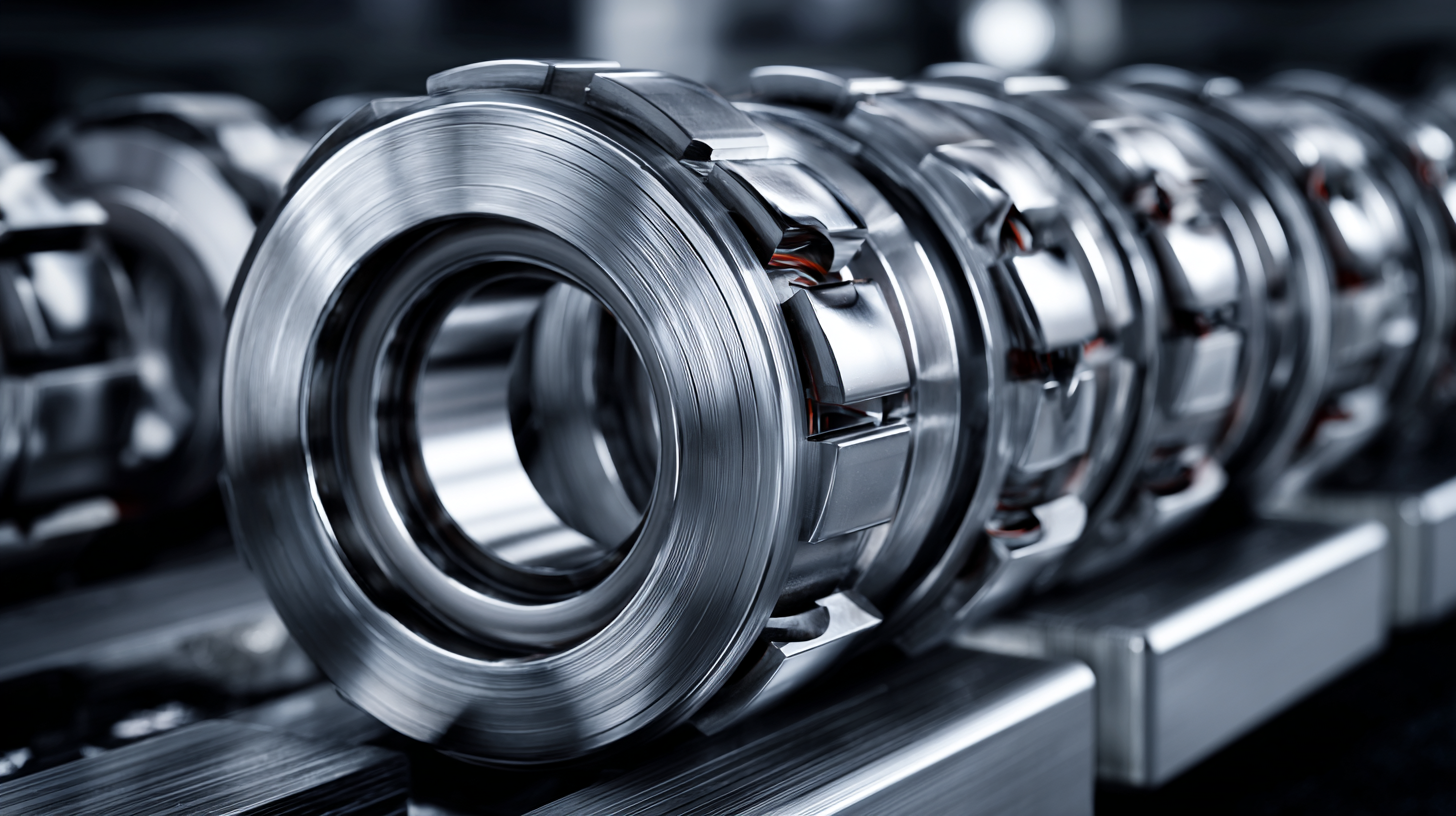

The future of machinery is rapidly evolving, driven by advancements in technology and increasing performance demands across various industries. One critical component that plays a pivotal role in this evolution is the Cylindrical Roller Bearing. According to a recent market report by Research and Markets, the global bearing market is projected to reach $103.5 billion by 2025, with cylindrical roller bearings accounting for a significant share due to their ability to handle heavy loads and high speeds. These bearings significantly enhance operational efficiency, reduce friction, and extend equipment lifespan, making them vital for applications in automotive, aerospace, and heavy machinery sectors. As machinery continues to integrate more sophisticated technologies such as IoT and automation, the demand for reliable and high-performance components like cylindrical roller bearings will become increasingly important in shaping the future of manufacturing and industrial operations.

How to Understand the Basics of Cylindrical Roller Bearings in Machinery

Cylindrical roller bearings (CRBs) play a crucial role in the performance of various machinery applications, including those in the rapidly growing wind energy sector. Understanding the basics of CRBs is essential for optimizing their use. These bearings are designed to handle significant radial loads while offering lower friction and higher speed capabilities. Their geometry allows for greater contact area, which enhances load distribution and ultimately prolongs bearing life.

In the context of wind turbines, where mainshaft loads are continually increasing due to larger turbine sizes and higher power outputs, the integrity and effectiveness of CRBs become even more apparent. The design and material selection for these bearings directly influence their performance under extreme conditions. Innovations focused on extending bearing life are therefore vital, as they help mitigate the stresses imposed by larger wind turbines, ensuring both reliability and efficiency in energy production. Understanding the operating principles of cylindrical roller bearings is key for engineers and manufacturers aiming to enhance machinery performance in this sector.

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

How to Identify Key Benefits of Using Cylindrical Roller Bearings

Cylindrical roller bearings have become essential components in modern machinery due to their ability to provide high efficiency and performance. According to a report by MarketsandMarkets, the global bearing market is projected to reach USD 80 billion by 2025, with cylindrical roller bearings accounting for a significant share due to their superior load-carrying capacity and reduced friction. These bearings are specifically designed to handle heavy radial loads, making them an ideal choice for applications in industries such as aerospace, automotive, and industrial machinery.

Cylindrical roller bearings have become essential components in modern machinery due to their ability to provide high efficiency and performance. According to a report by MarketsandMarkets, the global bearing market is projected to reach USD 80 billion by 2025, with cylindrical roller bearings accounting for a significant share due to their superior load-carrying capacity and reduced friction. These bearings are specifically designed to handle heavy radial loads, making them an ideal choice for applications in industries such as aerospace, automotive, and industrial machinery.

One of the key benefits of using cylindrical roller bearings is their ability to enhance machine reliability and longevity. A study conducted by the SKF Group found that using high-quality cylindrical roller bearings can increase the lifespan of machinery by up to 30%. Additionally, their design allows for easier maintenance and replacement, resulting in reduced downtime and lower operational costs. Furthermore, advancements in bearing materials and coatings have led to improved performance characteristics, such as higher temperature resistance and corrosion protection, further underscoring their importance in the evolving landscape of machinery.

How to Optimize Machinery Performance with Advanced Bearing Designs

Optimizing machinery performance is crucial in today’s competitive landscape, and cylindrical roller bearings play a pivotal role in achieving this goal. Advanced bearing designs not only reduce friction but also enhance load-carrying capacity, leading to improved efficiency. According to a report by the International Organization for Standardization (ISO), using high-quality bearings can increase machinery lifespan by up to 30%, significantly reducing operational costs associated with maintenance and downtime.

**Tips for Optimization:**

1. Select bearings with optimized design features, such as increased cross-sectional area, to enhance load distribution and decrease wear.

2. Ensure proper lubrication, as this can reduce friction and heat generation, enabling the machinery to operate smoothly and efficiently.

Furthermore, advancements in materials science have led to the development of hybrid bearings, which combine steel with ceramic materials. This innovation results in bearings that are not only lighter but also offer higher resistance to heat and corrosion. As outlined in a study by the World Bearing Association, such innovations can lead to a reduction in energy consumption by approximately 15%, making a significant impact on overall machinery efficiency in various industrial applications.

How to Maintain and Troubleshoot Cylindrical Roller Bearings Effectively

Cylindrical roller bearings are critical components in various machinery, providing the support needed to reduce friction and enhance efficiency. However, to ensure optimal performance, regular maintenance and effective troubleshooting are essential. According to a report by the American Bearing Manufacturers Association, improper maintenance can lead to bearing failures, costing manufacturers approximately $15 billion annually in lost productivity.

One of the key practices in maintaining cylindrical roller bearings is regular lubrication. Utilizing the correct type and amount of lubricant can prevent overheating and wear. Additionally, bearings should be inspected frequently for signs of wear, such as discoloration or unusual noises, which may indicate underlying issues. Implementing predictive maintenance techniques, such as vibration analysis, can significantly reduce unexpected downtimes and extend bearing life.

**Tips for Maintenance:**

- Always adhere to the manufacturer’s guidelines for lubrication intervals and types.

- Conduct routine inspections to monitor for misalignment or excessive play, as these can lead to early failure.

- Keep the surrounding environment clean and free from contaminants to prolong bearing lifespan.

By adopting these strategies, industries can enhance the reliability of their machinery while reducing maintenance costs.

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

| Parameter | Value | Description |

|---|---|---|

| Load Capacity | 2000 kg | Maximum load cylindrical roller bearings can support. |

| Speed Rating | 3000 RPM | Maximum rotational speed for optimal performance. |

| Lubrication Type | Grease | Recommended lubrication for longevity. |

| Common Failure Mode | Wear | Gradual degradation of bearing surfaces. |

| Maintenance Interval | Every 6 months | Recommended schedule for preventive maintenance. |

| Temperature Range | -20°C to +120°C | Optimal operating temperature range for bearings. |

| Installation Torque | 25 Nm | Recommended torque for secure installation. |

How to Predict Future Trends in Machinery Using Innovative Bearing Technology

The machinery industry is continuously evolving, driven by the need for enhanced performance and efficiency. Innovative bearing technology, particularly cylindrical roller bearings, plays a pivotal role in shaping future trends. According to a report by MarketsandMarkets, the global bearing market is projected to reach approximately $99 billion by 2026, growing at a CAGR of 6.3% from 2021. This growth is largely attributed to the increasing demand for high-performance machinery and the rising adoption of automation in industries such as aerospace, automotive, and manufacturing.

Cylindrical roller bearings are specifically designed to bear heavy loads and facilitate higher speeds, making them essential for modern machinery. Their ability to reduce friction and enhance energy efficiency is expected to drive their adoption. A study by ResearchAndMarkets notes that the demand for advanced bearing technologies, including these cylindrical designs, will be critical in meeting the machinery industry's requirements for durability and low maintenance. As industries move towards smart manufacturing, integrating predictive maintenance with innovative bearing solutions could revolutionize operational efficiency and reliability, making it a key focus area for manufacturers and engineers alike.

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat