10 Essential Tips for Choosing the Right Shandong Bearing

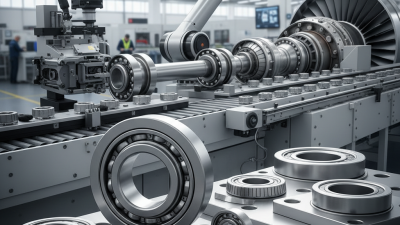

Choosing the right Shandong Bearing can significantly impact machinery performance. The global bearing market is projected to reach $110 billion by 2026, with a growing demand for high-quality products. Shandong Bearings are known for their robust engineering and reliability. They cater to various industries, from automotive to manufacturing.

Selecting the right bearing is crucial. The right choice influences durability and efficiency. According to industry reports, approximately 25% of bearing failures stem from poor selection. This statistic highlights the importance of understanding key factors when choosing Shandong Bearings. Among these are load capacity, material quality, and environmental conditions.

Incorporating these elements into the selection process can lead to improved machine performance and longevity. However, many overlook these factors, resulting in costly maintenance. Reflecting on one’s choices becomes vital, ensuring that the right Shandong Bearing is chosen for the specific application.

Understanding the Basics of Shandong Bearings

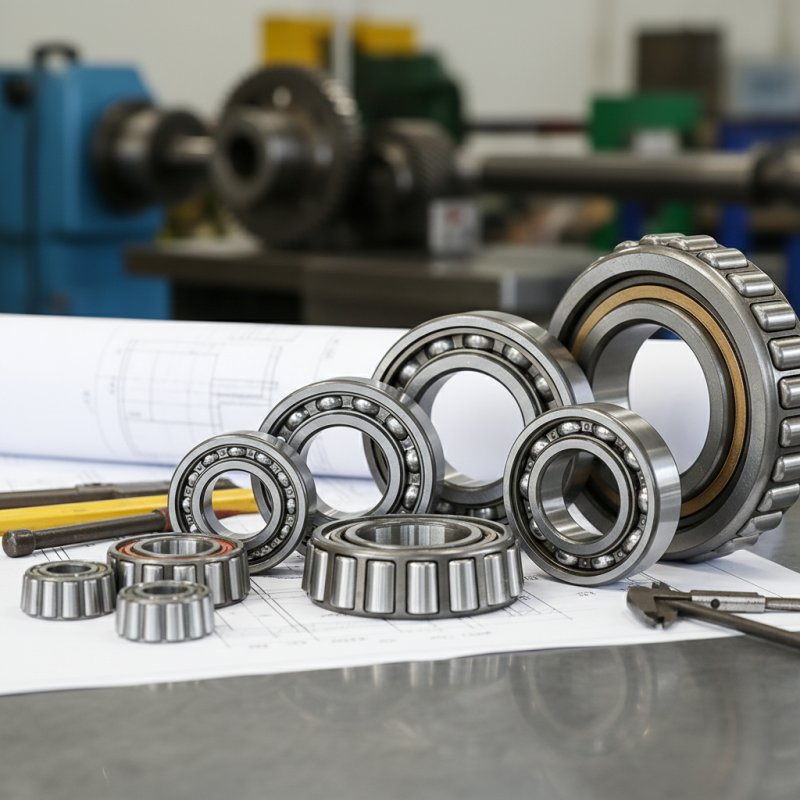

Shandong bearings are essential components in many machines. Understanding their basics is crucial for effective selection. These bearings support rotating shafts and reduce friction. They come in various sizes and types, tailored for different applications. When choosing, you must consider load capacity, speed ratings, and operating conditions. Each factor influences performance and lifespan.

The quality of materials used in manufacturing affects durability. Some bearings might not withstand heavy loads or extreme temperatures. You might encounter issues if you overlook this aspect. Sometimes, size or fit can be a concern. A mismatch can lead to quick wear or failure. It's important to double-check dimensions before making a purchase.

Be aware of the installation process too. Improper installation can lead to misalignment and premature failure. Even small errors can have significant consequences. Regular maintenance also plays a role in ensuring optimal performance. Neglecting it could result in costly downtime. Balancing quality and cost while considering these factors is key.

Distribution of Bearing Types Used in Shandong Industry

Identifying Your Specific Bearing Needs and Applications

When it comes to bearings, identifying your specific needs is crucial. Various applications demand different specifications. For example, industrial machinery often requires durable, high-load bearings, while automotive applications may focus on precision and low friction. According to a recent industry report, 70% of bearing failures stem from misapplication. Understanding your exact requirements helps reduce these risks significantly.

You should consider environmental factors, too. For instance, bearings used in harsh conditions need superior sealing and material resistance. Corrosion-resistant options are vital in marine applications. A study found that 40% of bearings fail prematurely due to inadequate protection against the environment. In contrast, operating conditions like temperature and humidity can influence performance. This makes thorough assessment necessary.

Don’t overlook the importance of load ratings. A bearing's load capacity affects its life cycle and efficiency. Load ratings should match the intended application closely. An improper match could lead to costly downtimes. There's no one-size-fits-all solution. Each application requires specific considerations, from load and speed to environmental factors. Reflecting on these details can enhance performance and longevity.

10 Essential Tips for Choosing the Right Shandong Bearing - Identifying Your Specific Bearing Needs and Applications

| Tip Number | Bearing Type | Application | Load Capacity (kg) | Speed Limit (RPM) |

|---|---|---|---|---|

| 1 | Deep Groove Ball Bearing | Electric Motors | 600 | 3000 |

| 2 | Angular Contact Bearing | Machine Tools | 800 | 4000 |

| 3 | Self-Aligning Ball Bearing | Agricultural Equipment | 500 | 2500 |

| 4 | Cylindrical Roller Bearing | Bicycle Hubs | 700 | 1800 |

| 5 | Tapered Roller Bearing | Automotive Wheel Hubs | 1000 | 1500 |

| 6 | Spherical Roller Bearing | Wind Turbines | 1200 | 1200 |

| 7 | Needle Roller Bearing | Small Appliances | 300 | 4000 |

| 8 | Thrust Ball Bearing | Heavy Machinery | 1500 | 1000 |

| 9 | Hybrid Ceramic Bearing | High-Speed Applications | 500 | 30000 |

| 10 | Sleeve Bearing | Fans and HVAC | 400 | 3600 |

Evaluating Material Quality and Specifications

When selecting a Shandong bearing, the material quality and specifications are crucial. Bearings are subjected to heavy loads and varied conditions. The right material determines their lifespan and performance. Common materials include steel and ceramic. Each has unique properties that impact durability.

Tip 1: Check for corrosion resistance. An environment with moisture may lead to premature failure. Tip 2: Look for precision in manufacturing. Flaws in this area can result in noise and vibration, deteriorating the performance.

Consider the specifications carefully. Load ratings influence how much weight the bearing can handle. Overlooking this can lead to a mismatch for your application. Additionally, examining tolerance levels is vital. Poor tolerance can cause unnecessary wear and tear, affecting efficiency. Make sure to balance these factors when making your decision.

Comparing Different Manufacturers and Their Reputation

When selecting bearings from Shandong, it’s crucial to analyze various manufacturers and their reputations. A report from the Bearing Industry Association states that over 70% of companies face quality issues in this sector. This statistic underlines the importance of choosing a reputable manufacturer. It’s advisable to investigate customer reviews and feedback. A single bad experience can lead to substantial operational downtime.

Manufacturers with strong track records often invest in quality control measures. According to a study, these manufacturers have a defect rate as low as 1% compared to 5% or higher for lesser-known firms. A thorough review of material sourcing and production practices is essential. Trustworthy manufacturers usually provide detailed documentation of these processes. Look for those that are transparent about their certifications.

However, not all well-reviewed manufacturers guarantee perfection. Some have hidden issues that only emerge over time. A company might excel in one area but falter in others. Reliability can sometimes be influenced by external factors, such as supply chain issues. Staying informed and continuously evaluating the performance of your chosen partner is fundamental.

Assessing Cost vs. Quality for Long-term Value

When choosing Shandong bearings, assessing cost versus quality is crucial. A recent industry report highlights that 70% of users prioritize quality over cost. While it may be tempting to choose the cheapest option, long-term savings usually come from higher quality products. Cheaper bearings deteriorate faster, leading to more frequent replacements. This can increase downtime and maintenance costs.

Quality bearings, even if pricier upfront, often boast extended lifespans. For example, a study found that high-quality bearings can last up to 50% longer than their lower-cost counterparts. Additionally, they tend to perform better under high-speed and heavy-load conditions. This performance reliability can be invaluable in industries where machinery downtime is costly.

Many buyers get caught in the low-cost trap. They might not consider the hidden costs associated with subpar products. Repair expenses and potential losses from equipment failure can quickly outweigh initial savings. Reflecting on these aspects is essential when making a selection. Understanding the long-term value should guide your purchasing decisions.

Related Posts

-

Top 2025 Guide to Flange Bearings Applications and Benefits Explained

-

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

2025 Top 10 Mounted Bearing Innovations You Need to Know

-

How to Choose the Right Self Aligning Ball Bearing for Your Application

-

Understanding the Factors Influencing Roller Bearing Prices: A Comprehensive Guide

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat