Top 5 Essential Pillow Block Bearings for Optimal Machinery Performance

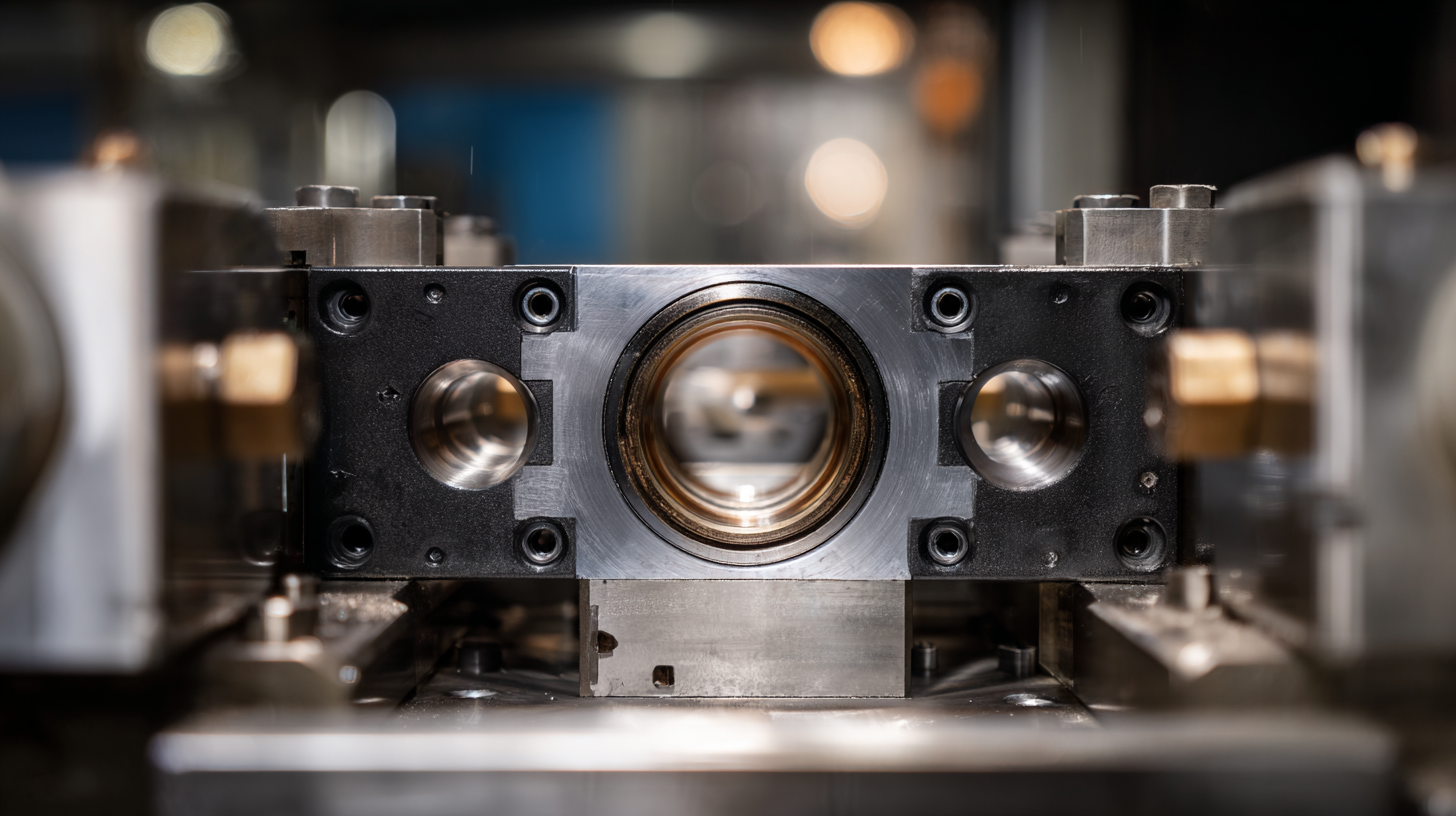

In the realm of industrial machinery, the significance of high-quality components cannot be overstated. One such crucial component is the Pillow Block Bearing, renowned for its ability to support rotating shafts while providing optimal alignment and stability. As industries evolve and strive for greater efficiency, the demand for reliable bearing solutions has never been more critical. This introduction highlights the top five essential Pillow Block Bearings that have emerged as frontrunners in the market, setting the standard for performance and durability.

Each of these selected Pillow Block Bearings has been meticulously evaluated based on key performance metrics, including load capacity, material quality, and ease of installation. Understanding the unique features of these bearings is vital for engineers and maintenance professionals alike, as these components directly impact the overall functionality and longevity of machinery. In this article, we will delve into the characteristics and benefits of these top-performing Pillow Block Bearings, ensuring that readers are equipped with the knowledge necessary to make informed decisions for their machinery needs in 2025 and beyond.

Essential Features of Top 5 Pillow Block Bearings for Machinery Efficiency

Pillow block bearings play a crucial role in enhancing the efficiency of machinery by providing support and stability to rotating shafts. When selecting the right pillow block bearing, several essential features must be considered. According to a report by the National Lubricating Grease Institute (NLGI), the lubrication quality and compatibility with the operating environment significantly influence bearing performance and longevity. Bearings designed with advanced sealing technologies, such as double-lip seals, not only protect against contaminants but also reduce the frequency of maintenance, ensuring continuous operation.

Another critical feature is the bearing material. A study published in the Journal of Tribology indicated that materials with high wear resistance and reduced friction coefficients, such as chrome steel and ceramic, can extend the operational lifespan of pillow block bearings. Furthermore, precision in manufacturing is paramount; bearings that meet ISO 9001 standards demonstrate improved dimensional accuracy and consistency, contributing to optimized machinery performance. Thus, selecting pillow block bearings with these essential features can significantly promote machinery efficiency and reliability.

Top 5 Essential Pillow Block Bearings for Optimal Machinery Performance

This chart presents the load rating (in kN) and the operating temperature range (in °C) of the top 5 essential pillow block bearings for optimal machinery performance.

Comparative Analysis of Different Types of Pillow Block Bearings

Pillow block bearings are critical components in machinery, ensuring smooth operation and longevity. When comparing different types of pillow block bearings, it is essential to consider factors such as material composition, sealing options, and mounting configurations.

Cast iron pillow block bearings, for instance, offer robust support and are ideal for heavy-duty applications. In contrast, thermoplastic versions are lighter and corrosion-resistant, making them suitable for less demanding environments.

Cast iron pillow block bearings, for instance, offer robust support and are ideal for heavy-duty applications. In contrast, thermoplastic versions are lighter and corrosion-resistant, making them suitable for less demanding environments.

Another significant aspect is the sealing mechanisms employed in various pillow block bearings. Some bearings feature double-lip seals that provide superior protection against contaminants, while others may have simpler designs for easier maintenance. Additionally, the design of the mounting surface plays a key role in stability and ease of installation.

Standard base-mounted pillow blocks are popular for their simplicity, whereas those with adjustable mounting allow for precise alignment, enhancing performance in precision applications. Understanding these differences is crucial for selecting the appropriate pillow block bearing to optimize machinery performance.

Key Applications of Pillow Block Bearings in Modern Industries

Pillow block bearings play a crucial role in ensuring the efficiency and reliability of modern machinery across various industries. One of the most prominent applications is in manufacturing, where these bearings support rotating shafts, providing stability and reducing friction. Their ability to adapt to misalignment makes them ideal for heavy-duty environments, ensuring that production lines run smoothly and reducing the risk of unexpected downtime.

Additionally, pillow block bearings are widely utilized in the agricultural sector, where they facilitate the operation of equipment such as conveyor systems and irrigation pumps. By offering strong support and easy installation, they contribute to the overall performance and longevity of agricultural machinery. The food processing industry also benefits from pillow block bearings, as they can withstand washdowns and corrosive environments, ensuring hygiene and efficiency in production processes. These key applications highlight the integral role pillow block bearings play in enhancing functionality and maintaining optimal performance in various industrial settings.

Top 5 Essential Pillow Block Bearings for Optimal Machinery Performance

| Bearing Type | Load Capacity (kg) | Speed Rating (RPM) | Temperature Range (°C) | Key Application |

|---|---|---|---|---|

| Standard Pillow Block | 1500 | 1200 | -20 to 100 | Conveyor Systems |

| Heavy-Duty Pillow Block | 5000 | 900 | -30 to 120 | Construction Equipment |

| Stainless Steel Pillow Block | 2000 | 1500 | -40 to 150 | Food Processing |

| Vibration-Dampening Pillow Block | 1800 | 1000 | -10 to 120 | Mining Machinery |

| High-Speed Pillow Block | 1200 | 3000 | 0 to 100 | Textile Machines |

Performance Metrics to Evaluate the Best Pillow Block Bearings

When evaluating pillow block bearings for optimal machinery performance, it is essential to consider several performance metrics. Key factors such as load capacity, temperature stability, and maintenance intervals significantly influence their efficiency and longevity. A recent product launch has introduced re-engineered mounted ball bearings, designed with industry-standard materials that enhance their robustness and heat resistance. Such advancements in design and material can help minimize downtime and ensure consistent performance, especially in demanding applications.

When evaluating pillow block bearings for optimal machinery performance, it is essential to consider several performance metrics. Key factors such as load capacity, temperature stability, and maintenance intervals significantly influence their efficiency and longevity. A recent product launch has introduced re-engineered mounted ball bearings, designed with industry-standard materials that enhance their robustness and heat resistance. Such advancements in design and material can help minimize downtime and ensure consistent performance, especially in demanding applications.

In addition to traditional metrics, integration of smart technology in bearing systems has emerged as a game changer. For instance, a new wireless condition-monitoring sensor provides real-time feedback on bearing conditions, measuring vital indicators like vibration and temperature. This proactive approach allows operators to detect potential issues early, facilitating timely maintenance and reducing the risk of catastrophic failures. By leveraging these innovative performance metrics and technologies, machinery operators can ensure optimal performance and extend the lifespan of their equipment.

Future Trends in Pillow Block Bearing Technology for 2025

As we approach 2025, the pillow block bearing industry is poised for significant advancements driven by emerging technologies and changing market demands. The projected growth rate for the global pillow block bearing market indicates a compound annual growth rate (CAGR) of approximately 5.3% during the next few years, underscoring the increasing need for optimized machinery performance across various sectors. This growth is primarily fueled by the heightened focus on energy efficiency and automation in manufacturing processes.

Innovations in materials and design are set to play a pivotal role in shaping the future of pillow block bearings. The incorporation of advanced engineering polymers and composite materials promises to enhance durability while reducing weight. Furthermore, with the rising prominence of predictive maintenance technologies, intelligent pillow block bearings equipped with integrated sensors will enable real-time performance monitoring, significantly reducing downtime. Industry reports forecast that by 2025, around 30% of new installations will adopt smart bearing technology, reflecting a transformative shift towards more interconnected and efficient machinery.

In line with the trends highlighted at events such as the Guangzhou Sourcing Fair: Houseware & Hardware, industry stakeholders are keen on showcasing these technological advancements, promoting products that not only meet current performance standards but also align with sustainability goals. As manufacturers continue to seek out cutting-edge solutions, the advent of intelligent and eco-friendly pillow block bearings will undoubtedly redefine optimal machinery performance in the coming years.

Related Posts

-

How to Choose the Right Self Aligning Ball Bearing for Your Application

-

2025 Top 10 Mounted Bearing Innovations You Need to Know

-

Exploring the Science Behind Miniature Bearings and Their Role in Modern Technology

-

Understanding the Factors Influencing Roller Bearing Prices: A Comprehensive Guide

-

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat