How to Choose the Right Fan Bearing for Optimal Performance and Longevity

Choosing the right fan bearing is crucial for ensuring optimal performance and longevity of any cooling system. Fan bearings serve as the core component that allows smooth rotation, thereby influencing the efficiency and noise levels of the fan. With various types of fan bearings available, such as ball bearing, sleeve bearing, and fluid dynamic bearing, understanding their unique characteristics can significantly impact the overall functionality and lifespan of your equipment.

In the realm of cooling solutions, selecting the appropriate fan bearing involves evaluating factors such as load capacity, speed, operating environment, and noise tolerance. Each bearing type presents distinct advantages and limitations, making it essential to align your choice with the specific demands of your application. By carefully considering these elements, you can enhance the reliability and performance of your cooling systems, ensuring they meet the operational needs without compromising on energy efficiency or durability.

Overall, this guide aims to provide insights into the various fan bearing options available and help you make an informed decision that optimizes performance and prolongs the life of your fans. Whether you're involved in manufacturing, HVAC, or consumer electronics, understanding how to choose the right fan bearing is an invaluable skill that will yield substantial benefits in your projects.

Understanding Different Types of Fan Bearings: A Comprehensive Guide

When selecting a fan bearing, it is essential to understand the various types available, as each type presents unique characteristics that can affect performance and longevity. The two most common types are sleeve bearings and ball bearings. Sleeve bearings utilize a plain bearing surface and are often more economical, making them suitable for applications with lower speed and load requirements. However, they may generate more friction and heat, potentially leading to a shorter lifespan compared to other options.

On the other hand, ball bearings consist of small balls that reduce friction between the moving parts, allowing for smoother operation, higher speeds, and better thermal performance. They are often employed in applications where consistent operation is crucial, such as in computer cooling fans or high-performance industrial systems. While they tend to be more expensive, their durability and longevity make them a preferred choice for demanding environments.

Additionally, it is vital to consider factors such as noise levels, temperature tolerance, and maintenance requirements when choosing the right bearing type for your needs. Selecting the appropriate fan bearing not only ensures optimal performance but also extends the lifespan of the device, thus providing a better return on investment over time. Understanding these nuances can empower users to make informed decisions tailored to their specific applications.

This bar chart illustrates the performance ratings of different types of fan bearings. Ball bearings typically offer the highest performance, while sleeve bearings lag behind. Fluid bearings also provide solid performance, and magnetic bearings lead with an outstanding rating.

Factors Influencing Bearing Performance in Fan Applications

When selecting the right fan bearing, several critical factors must be taken into account to ensure optimal performance and longevity. One of the primary considerations is the operational environment. Bearings are subjected to various conditions such as temperature, humidity, and particulate exposure. For instance, bearings operating in high-temperature environments must be made from materials that can withstand heat without degrading, while those in dusty settings may require enhanced sealing mechanisms to prevent contamination.

Another significant factor influencing bearing performance in fan applications is load and speed ratings. Each bearing type has specific load tolerance and rotational speed capabilities, which can affect their efficiency and lifespan. When a bearing operates outside of its rated limits, it can lead to premature wear or failure. Therefore, understanding the fan's operational demands, including static and dynamic loads and the anticipated speed range, is essential in selecting a bearing that will perform reliably over time. Additionally, lubrication methods play a vital role in reducing friction and wear; selecting the appropriate lubricant based on the bearing material and application environment can significantly impact overall performance and longevity.

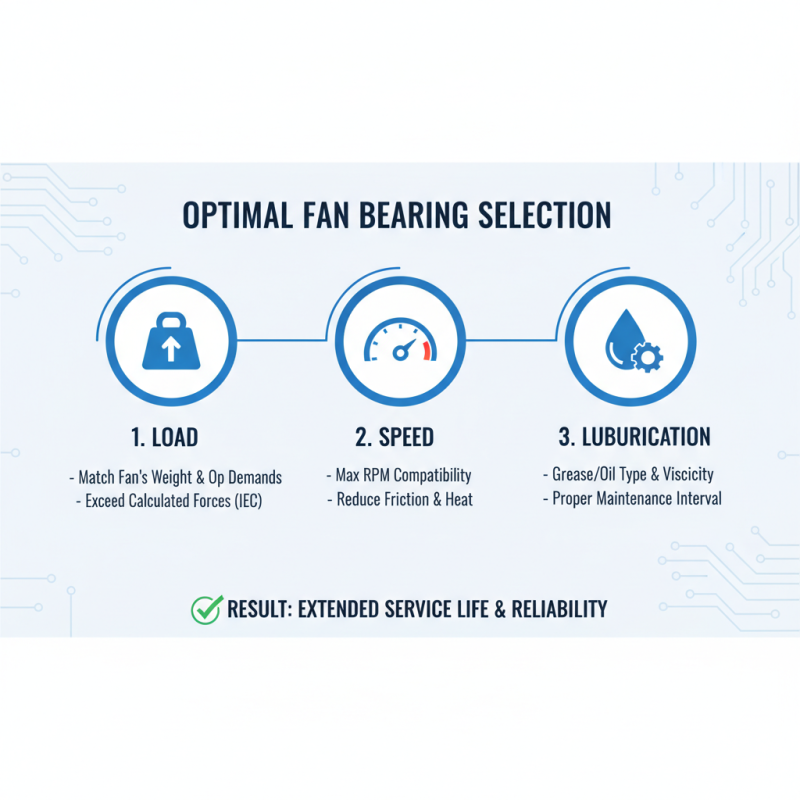

Key Parameters for Selecting Bearings: Load, Speed, and Lubrication

When selecting the right fan bearing for optimal performance and longevity, three critical parameters must be considered: load, speed, and lubrication. The bearing load capacity is essential, as it needs to correspond with the weight and operational demands of the fan. According to the International Electrotechnical Commission (IEC), bearings should be selected based on dynamic load ratings that exceed the calculated forces they will encounter during operation. For instance, a properly rated bearing will help prevent premature failures and extend the overall service life, particularly in high-demand industrial applications.

Speed is another vital factor in bearing selection. Bearings are designed to operate efficiently within specific speed ranges, and exceeding these limits can lead to significant wear and heat generation. The American National Standards Institute (ANSI) highlights that selecting a bearing with an appropriate speed rating can enhance performance and reduce vibration, which is crucial for minimizing noise levels in applications where sound is a concern, such as HVAC systems and electronic devices.

Lubrication also plays a pivotal role in ensuring optimal bearing performance. The type of lubricant can influence not only the friction levels but also the bearing's operating temperature and lifespan. According to a report by the International Society of Tribologists and Lubrication Engineers (ISTLE), using the correct lubricant significantly reduces wear rates and extends maintenance intervals, with properly lubricated bearings demonstrating up to 50% longer life compared to their inadequately lubricated counterparts. By focusing on these parameters, one can effectively choose bearings that meet the demands of their specific applications, ensuring both efficiency and durability.

Impact of Bearing Material on Fan Longevity and Efficiency

The choice of bearing material is crucial in determining the longevity and efficiency of a fan. Different materials exhibit varying properties that affect performance under specific operating conditions. For instance, metal bearings, often used for their durability, can withstand higher loads and temperatures, making them ideal for heavy-duty applications. However, they may also experience increased friction, which can lead to energy inefficiency and heat generation over time.

In contrast, composite or ceramic bearings tend to offer lower friction coefficients, translating to greater energy efficiency and quieter operation. The lightweight nature of these materials reduces the overall load on the fan motor, allowing for prolonged service life. Additionally, their resistance to corrosion and wear can contribute significantly to fan longevity, especially in environments where exposure to moisture or corrosive substances is a concern. Choosing the appropriate bearing material not only enhances operational efficiency but can also lead to significant cost savings in maintenance and replacement over the lifecycle of the fan.

Maintenance Best Practices for Extending Fan Bearing Life

Maintaining fan bearings is crucial for ensuring optimal performance and longevity. In industrial settings, proper maintenance can significantly reduce downtime and operational costs. According to a report by the User Group for Fan Technology (UGFT), up to 40% of fan failures are linked to bearing issues. Regularly checking lubrication levels and ensuring bearings are free from contaminants can help mitigate unexpected breakdowns. Implementing a routine maintenance schedule, which includes cleaning and inspecting bearings, is essential for prolonging life and preventing costly repairs.

Another vital aspect of maintenance is temperature control. Studies have shown that for every 10°C increase in operating temperature, the lifespan of a bearing can be reduced by half. Therefore, monitoring operational temperatures and employing proper cooling techniques can enhance bearing longevity. Additionally, vibration analysis is a critical practice to detect early signs of wear and imbalance in fan systems. According to the International Society of Automation, regular vibration monitoring can increase equipment life by up to 30%. By adopting these best practices, businesses can ensure their fan bearings deliver optimal performance while extending their service life significantly.

Related Posts

-

Top 10 Germany Made Bearings for Exceptional Performance and Reliability

-

Why Japan Bearings Are Essential for Industry and How to Choose the Best Ones

-

What is the Average Roller Bearing Price and Factors Affecting It

-

Top 2025 Guide to Flange Bearings Applications and Benefits Explained

-

Top Linqing Bearing Applications and Benefits for Industrial Uses

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat