How to Choose the Best Small Bearing for Your Project?

Choosing the right small bearing for your project can significantly impact overall performance. According to a report by the International Federation of Robotics, the global bearing market, particularly small bearings, is projected to reach $6 billion by 2025. This shows the growing demand for precision and reliability in various applications.

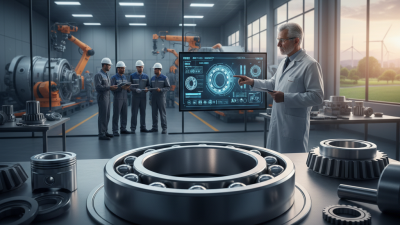

Industry expert Dr. Emily Carter states, "Selecting the right small bearing is crucial for ensuring efficiency and durability in mechanical systems." Her insight emphasizes the importance of evaluating factors like load capacity and speed ratings. Different projects require distinct specifications, which can lead to confusion. Understanding these details is vital for making informed decisions.

In a world where specifications are critical, minor oversights can result in inefficiencies. Evaluating small bearings involves more than just choices; it requires careful consideration of operating conditions, materials, and design. A well-chosen small bearing fosters reliability, but the learning curve is steep. Failure to address these factors can lead to project setbacks, demonstrating the importance of thorough research and expert guidance.

Understanding the Different Types of Small Bearings and Their Applications

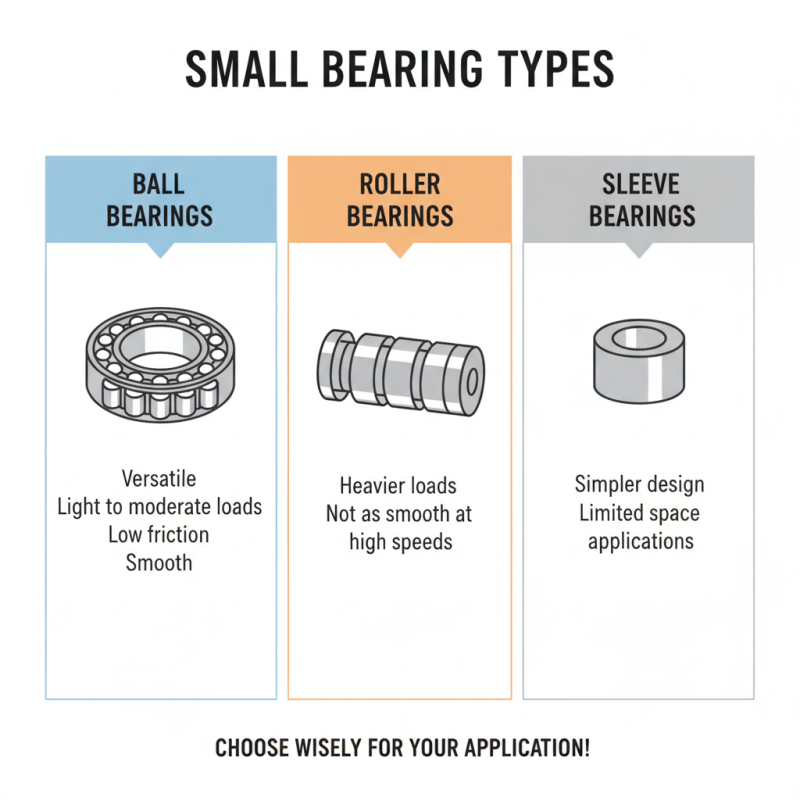

When selecting a small bearing, understanding the various types is crucial. There are ball bearings, roller bearings, and sleeve bearings, each serving different functions. Ball bearings are versatile and work well in light to moderate loads. They are known for their low friction and smooth performance. Roller bearings, on the other hand, can handle heavier loads but may not perform as smoothly under high speeds. Sleeve bearings are simpler, often used in applications with limited space.

Consider your project's specific needs. Will it face heavy loads? Or is speed the priority? Noise levels and environmental factors also play a role. For example, some materials resist corrosion but may generate more noise. It’s important to balance these factors. Using the correct type of bearing enhances longevity but can be tricky.

You might find yourself torn between options that seem equally appealing. This decision-making process can be frustrating. Even after thorough research, uncertainties arise. It’s a good idea to seek advice from experienced individuals. They can offer valuable insights based on their experiences, helping you avoid common pitfalls. Making the right choice requires careful consideration and sometimes a bit of trial and error.

Key Specifications to Consider: Load Capacity, Speed, and Lubrication

Choosing the right small bearing involves understanding key specifications. Load capacity is vital. It determines how much weight the bearing can handle. If you underestimate this, your project might fail. High-load situations require robust bearings to maintain performance.

Speed is another critical factor. Bearings operate at various RPMs. Selecting a bearing with insufficient speed rating can lead to overheating. It can cause wear and drastically reduce lifespan. Consider the application carefully. Look at the expected RPM and choose accordingly.

Lubrication impacts performance too. Proper lubrication reduces friction and prolongs bearing life. Some bearings come pre-lubricated; others need ongoing maintenance. A lack of lubrication can lead to premature failure. Think about your project’s environment and how often you can service the bearing. Avoid overlooking this aspect, as it could ruin your design. Each detail matters significantly. Reflect on your choices; they shape the success of your project.

Load Capacity and Speed Comparison of Small Bearings

The Role of Material and Design in Bearing Performance and Longevity

When choosing the best small bearing, material and design are crucial factors. Bearings come in various materials. Common options include steel, ceramic, and plastic. Steel offers high strength, while ceramics provide excellent corrosion resistance. Plastic bearings are lightweight and suitable for specific environments. Each material type will influence performance and longevity.

Tip: Consider the environment where the bearing will operate. Will it face extreme temperatures or moisture? Each condition tests the bearing's resilience. Choose a material that matches your working conditions.

Design plays a vital role too. The shape and configuration can affect load distribution. Some designs are optimized for speed, while others focus on durability. A well-designed bearing reduces friction and improves lifespan.

Tip: Look for bearings with seals or shields. These features keep dirt and moisture out, enhancing longevity. Keep in mind that a more complex design might not always yield better results. Sometimes, simplicity offers reliability.

Choosing the best small bearing is not a straightforward task. A balance between material, design, and application is essential. Reflect on your project's unique requirements, and invest time in this decision.

How to Choose the Best Small Bearing for Your Project?

| Bearing Type | Material | Load Capacity (kg) | Speed Rating (RPM) | Longevity (hours) |

|---|---|---|---|---|

| Miniature Ball Bearing | Stainless Steel | 10 | 30,000 | 5,000 |

| Shielded Ball Bearing | Chrome Steel | 20 | 25,000 | 4,000 |

| Plastic Bearing | Nylon | 5 | 15,000 | 3,000 |

| Thrust Bearing | Brass | 15 | 20,000 | 4,500 |

| Ceramic Bearing | Silicon Nitride | 25 | 40,000 | 10,000 |

Common Industry Standards for Small Bearings: ISO and AFBMA Guidelines

When selecting small bearings, understanding the relevant industry standards is crucial. Two of the most recognized standards are the ISO (International Organization for Standardization) and AFBMA (Anti-Friction Bearing Manufacturers Association) guidelines. ISO 4941:2016 outlines the essential requirements for rolling bearings. It highlights dimensions, tolerances, and load ratings that must fit specific applications. Following these standards can improve product reliability and performance by ensuring uniformity and compatibility across different projects.

AFBMA sets forth standards such as AFBMA 9, which defines bearing classes based on precision. These guidelines emphasize critical metrics like axial load capacity and radial runout. For example, a bearing with a higher radial runout may lead to vibrations. This can ultimately affect the lifespan of machinery. Moreover, the AFBMA guide underlines the importance of choosing the correct lubricant to avoid premature wear.

It’s worth noting that not all bearings meet these rigorous standards. Some manufacturers may cut corners on material quality. This could lead to durability issues down the line. Moreover, varying interpretations of guidelines can create inconsistencies in product offerings. Acknowledging these complexities is important for making informed choices tailored to your project needs.

Evaluating Cost vs. Quality: Making the Best Investment for Your Project

When selecting a small bearing for your project, cost and quality are often at odds. The bearing industry reports indicate that about 70% of projects prioritize initial cost over long-term durability. This approach can lead to significant issues down the line. A low-cost bearing may save money initially, but it could fail quickly, leading to higher replacement costs and project delays.

Quality bearings, on the other hand, may have a higher upfront cost. However, they often offer superior performance and longevity. Data suggests that investing in quality can extend operational life by 50% or more. This is crucial for projects that require reliability, especially in demanding applications. Keep in mind that choosing a cheaper option now does not always equate to savings.

It’s critical to evaluate your project’s specific needs against these costs. A detailed analysis of expected usage, load demands, and environmental factors can guide your decision. Many projects overlook these details, which often leads to poor long-term choices. Investing in high-quality bearings could prevent future headaches and enable smoother operations. Balancing cost with quality is not simple, but thorough planning can yield better outcomes.

Related Posts

-

Top 10 Machine Bearings: Best Types for Optimal Performance and Longevity

-

How to Choose the Right Self Aligning Ball Bearing for Your Application

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

2025 How to Select the Best Machinery Bearings for Your Industrial Needs

-

What is Japan Bearing and How It Impacts Industrial Applications

-

2025 Top Germany Made Bearings Review and Buying Guide

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat