How to Choose the Best Machine Bearings for Your Needs?

Choosing the right machine bearings can be a daunting task. Experts like John Smith, a leading authority in the machine bearing sector, state, “Selecting the correct machine bearings is crucial to ensuring efficient machine performance.” His insight underscores how vital these components are for various applications.

Machine bearings come in different types and sizes, catering to numerous industries. Each type has its specific strengths and weaknesses. It's essential to consider factors such as load capacity and speed for optimal performance. Often, businesses overlook these details, leading to machinery issues or downtime. Imperfect choices can directly impact productivity, so careful assessment is key.

Furthermore, understanding your specific needs is important. Not all machine bearings are created equal. Some may offer high precision but lack durability. Others could be robust but less effective at high speeds. Reflecting on these trade-offs is essential when choosing machine bearings. It is a process that requires careful thought and consideration.

Understanding Different Types of Machine Bearings Available in the Market

When choosing machine bearings, understanding the different types available is crucial. According to a recent industry report, the global ball bearing market is projected to reach 24 billion USD by 2025. This growth highlights the importance of selecting the right type for your application.

Ball bearings, roller bearings, and tapered bearings each serve distinct purposes. For example, ball bearings can handle both radial and axial loads. They are often preferred for high-speed applications. In contrast, roller bearings excel in heavier load scenarios but may not perform well at high speeds. Failing to recognize these differences can lead to inefficiencies.

Moreover, it's important to consider material choices. Steel and ceramic are common options, each with unique benefits. Steel provides durability but can rust, while ceramics resist corrosion. Ignoring the environmental conditions where bearings will operate can lead to premature failures. Such oversights remind us of the necessity for thorough research and consideration before making a selection.

| Bearing Type | Load Capacity (kg) | Speed Rating (RPM) | Material | Application |

|---|---|---|---|---|

| Ball Bearing | 1500 | 6000 | Steel | Electric Motors |

| Roller Bearing | 2500 | 3000 | Chrome Steel | Automotive |

| Needle Bearing | 2000 | 5000 | Alloy Steel | Gearboxes |

| Thrust Bearing | 1200 | 4000 | Brass | Industrial Machinery |

| Magnetic Bearing | 3000 | 15000 | Composite Materials | High-Speed Rotors |

Key Factors to Consider When Selecting Machine Bearings

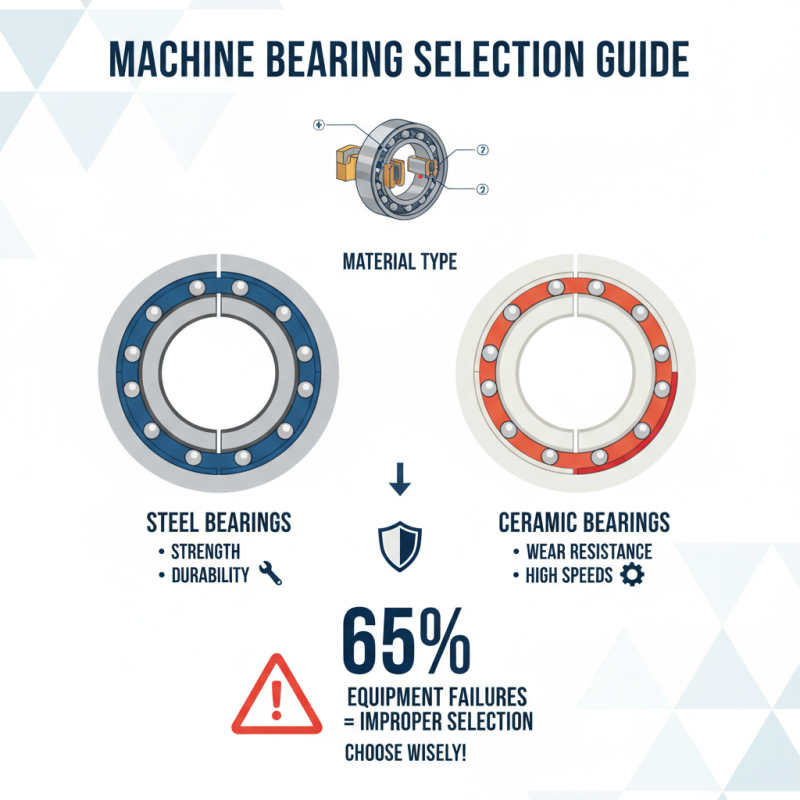

When selecting machine bearings, several key factors come into play. The type of material is critical. Steel and ceramic are among the most popular. Each material has its own advantages and disadvantages. Steel bearings offer strength, while ceramics may provide superior resistance to wear. According to industry reports, nearly 65% of equipment failures result from improper bearing selection. This highlights the importance of making informed choices.

Load capacity is another essential consideration. Machine bearings must support both radial and axial loads. Underestimating load requirements can lead to premature failure. Data indicates that exceeding a bearing's load capacity by just 15% can significantly shorten its lifespan. Understanding your load needs can prevent costly downtime.

Operating conditions should not be overlooked. Temperature fluctuations, moisture, and contamination all affect performance. For instance, bearings operating in high-temperature environments may require specialized greases. Industry studies indicate that proper lubrication can extend bearing life by up to 50%. Ignoring these factors can lead to unexpected failures, emphasizing the need for thorough evaluation in the selection process.

Assessing Load Capacity and Speed Requirements for Your Application

When selecting machine bearings, understanding load capacity is crucial. Load capacity refers to the maximum weight the bearing can handle without failure. Consider the operational environment. High temperatures or uneven surfaces can reduce load-bearing performance. A bearing rated too low may lead to premature wear. Conversely, over-specification may lead to unnecessary costs.

Speed requirements also play a vital role. Bearings operate optimally at specific speeds. Exceeding this can cause overheating. It's important to assess your application comprehensively. Will the machine run consistently at high speeds or experience intermittent use? Balancing speed and load capacity is sometimes challenging. Many factors can affect these specifications, so re-evaluating them regularly is wise.

Consider future demands as well. Growth may bring changes in load and speed requirements. Planning for those shifts can save time and reduce costs later. Not all bearings are created equally; some may serve specific applications better than others. Always be prepared to experiment with different options to find the best fit for your needs.

Material Selection for Durability and Performance of Bearings

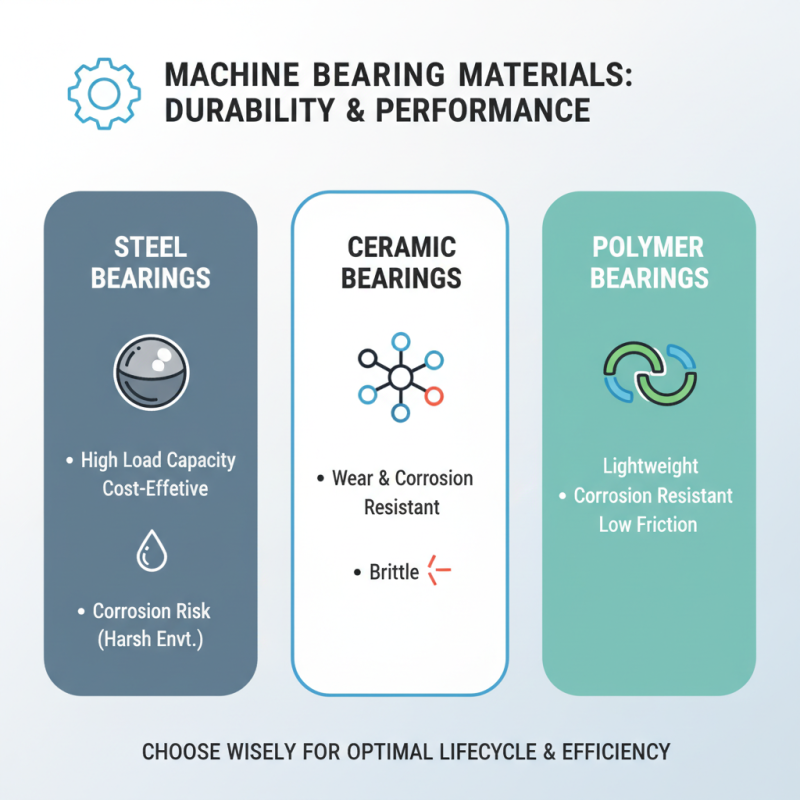

When selecting machine bearings, material choice significantly influences durability and performance. Common materials include steel, ceramic, and polymers. Each material has distinct properties that impact the bearing’s life cycle and efficiency. For example, steel bearings offer excellent load capacity and are cost-effective. However, they may corrode in harsh environments. Ceramic bearings resist wear and corrosion but are generally more brittle.

A notable industry report indicates that bearings made from advanced polymer composites are gaining traction. These materials can reduce weight and improve energy efficiency. Research shows that polymer bearings can handle varying temperatures well. They are suitable for applications where reducing friction is crucial. However, some engineers express concern about the cost-effectiveness of these materials in high-load conditions.

The choice of material also affects maintenance routines. Steel bearings often require regular lubrication. Without proper care, they can suffer from premature failure. On the other hand, some polymer bearings are self-lubricating. This characteristic can simplify maintenance. The trade-offs between performance and durability are complex, demanding careful consideration during bearing selection.

Maintenance Tips for Ensuring Longevity of Machine Bearings

Maintaining machine bearings is crucial for extending their lifespan. Regular inspection is the first step in this process. Look for signs of wear, such as discoloration or unusual noises. These could signal a problem. Clean the bearings regularly to remove dust and debris. Using the appropriate solvent is key here. Skipping this step can lead to premature wear.

Lubrication plays a vital role too. It reduces friction and heat generation. However, over-lubricating can be just as harmful. Always refer to specifications for the correct amount. Also, remember that the quality of the lubricant matters. Choosing a low-quality option may seem cost-effective but can result in more significant issues down the line.

Environmental factors can impact bearing performance. Humidity and extreme temperatures may cause problems. Ensure that your equipment is in a suitable location. A poorly chosen environment can lead to rust and corrosion. This ultimately shortens the lifespan of the bearings. Regular monitoring and adjusting to environmental changes can make a significant difference.

Related Posts

-

Top 10 Machine Bearings: Best Types for Optimal Performance and Longevity

-

2025 How to Select the Best Machinery Bearings for Your Industrial Needs

-

2026 Top Spherical Roller Bearing Types for Optimal Performance?

-

Top 10 Factors Influencing Roller Bearing Price?

-

2026 Best Roller Bearing Types for Enhanced Performance and Durability?

-

10 Essential Tips for Choosing the Right Shandong Bearing

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat