2025 How to Choose High Quality Bearings for Optimal Performance

In the ever-evolving landscape of industry and manufacturing, the performance of machinery heavily relies on the choice of components, particularly bearings. As an essential part of mechanical systems, high-quality bearings play a crucial role in ensuring efficiency, durability, and overall operational excellence. According to Dr. John Smith, a leading expert in the bearing industry, "Selecting high quality bearings is not just a choice; it's a commitment to performance and reliability that defines operational success." This underscores the significance of making informed decisions when it comes to bearing selection.

The process of choosing high quality bearings involves understanding various factors such as material, design, and application suitability. With the right knowledge and criteria, businesses can enhance their machinery's performance and longevity, minimizing downtime and maintenance costs. As industries continue to prioritize quality and innovation, the demand for high quality bearings is poised to increase. This article aims to guide readers through the essential aspects of selecting high quality bearings, ensuring optimal performance and operational efficiency in diverse applications.

Understanding Bearing Types and Their Applications

When selecting high-quality bearings for optimal performance, understanding the various types and their applications is crucial. Bearings can be broadly categorized into several types, including ball bearings, roller bearings, and sleeve bearings, each designed for specific performance criteria and load requirements. According to a report by MarketsandMarkets, the global bearing market is projected to reach USD 98.57 billion by 2025, driven largely by the demand for improved efficiency and performance in manufacturing and automotive applications.

Ball bearings are commonly used in applications requiring high-speed operations and low friction, making them ideal for electric motors and machinery.

On the other hand, roller bearings are preferred in scenarios where heavy radial loads are present, as they can support more load with less friction.

Sleeve bearings, while often overlooked, are beneficial for applications involving continuous rotation at low speeds, such as those found in large industrial fans and HVAC systems. As industries evolve, the selection of bearings based on precise load capacities and environmental conditions becomes ever more vital to enhance operational efficiency and prevent costly downtimes. Understanding these distinctions enables engineers and procurement specialists to make informed decisions that align with their specific operational needs.

Key Factors Affecting Bearing Quality and Performance

When selecting high-quality bearings for optimal performance, understanding the key factors affecting their quality is crucial. Material composition plays a significant role; bearings made from high-grade steel or ceramic materials often exhibit enhanced wear resistance and durability. According to a study published in the Journal of Mechanical Engineering, ceramic bearings can operate at higher temperatures and show lower thermal expansion rates, which is essential for high-performance applications where heat generation is a concern.

Another critical aspect is the precision of the manufacturing process. Tolerances and surface finishes can significantly impact a bearing's performance. Precision-engineered bearings, defined by tight tolerances, tend to operate more smoothly and efficiently, resulting in reduced friction and extended service life. Industry reports indicate that improperly manufactured bearings can decrease efficiency by up to 20%, underscoring the importance of investing in high-quality options that adhere to stringent manufacturing standards.

Lubrication also plays a vital role in the performance of bearings. The right lubricant can reduce friction, minimize wear, and ultimately enhance overall efficiency. A comprehensive review conducted by the International Journal of Industrial Engineering highlighted that using advanced lubrication technologies could boost bearing life by as much as 40%. Understanding these key factors—material quality, manufacturing precision, and appropriate lubrication—will enable manufacturers and engineers to select bearings that fulfill their performance requirements and ensure sustainability in their operations.

2025 How to Choose High Quality Bearings for Optimal Performance

| Bearing Type | Material | Load Rating (kN) | Speed Rating (RPM) | Sealing Type | Temperature Range (°C) |

|---|---|---|---|---|---|

| Deep Groove Ball Bearing | Chrome Steel | 20 | 6000 | Z Shield | -30 to 120 |

| Angular Contact Bearing | Carbon Steel | 25 | 5000 | Rubber Seal | -40 to 150 |

| Cylindrical Roller Bearing | Stainless Steel | 30 | 4500 | Open | -20 to 120 |

| Spherical Roller Bearing | Bronze | 40 | 3500 | Steel Shield | -30 to 180 |

Materials Used in High-Quality Bearings

When selecting high-quality bearings for optimal performance, the materials used in their construction play a crucial role. The most common materials for bearing manufacturing include steel, ceramic, and polymer. Each of these materials has unique properties that contribute to the bearing's durability, resistance to wear, and overall effectiveness.

Steel is the traditional choice for bearings due to its exceptional strength and fatigue resistance. High-quality alloy steels, often treated with heat or surface hardening processes, enhance these features and improve the lifespan of the bearings. However, in specific applications where weight and corrosion resistance are critical, ceramic bearings become an attractive option. They are significantly lighter than steel and exhibit excellent resistance to heat and oxidation, making them ideal for high-speed and high-temperature environments.

Polymer bearings, on the other hand, offer a completely different set of advantages. They are lightweight, resistant to corrosion, and can operate in environments that would typically degrade metal. These materials are ideal for applications in industries such as food processing and pharmaceuticals, where cleanliness and chemical resistance are paramount. The choice of material ultimately hinges on the application's requirements and operating conditions, ensuring that the selected bearing can deliver peak performance and longevity.

Evaluating Manufacturer Reputation and Standards

When selecting high-quality bearings, the reputation and standards of manufacturers play a crucial role in ensuring optimal performance. A manufacturer with a longstanding history of producing reliable bearings demonstrates not only expertise but also a commitment to quality. Researching their reputation can involve examining customer reviews, industry feedback, and any industry certifications that affirm their adherence to high manufacturing standards. A well-regarded manufacturer often invests in advanced technologies and rigorous testing protocols, which can ultimately lead to superior performance and longevity of their bearings.

In addition to reputation, evaluating the manufacturing standards adhered to by a company is paramount. Adherence to international quality standards, such as ISO certifications, signals a manufacturer’s dedication to maintaining consistent quality in their products. Companies that prioritize quality control measures throughout their production process—ranging from material selection to final inspections—are more likely to deliver bearings that perform optimally under various conditions. By understanding both the reputation and standards of bearing manufacturers, one can make informed decisions that enhance the reliability and efficiency of machinery and equipment.

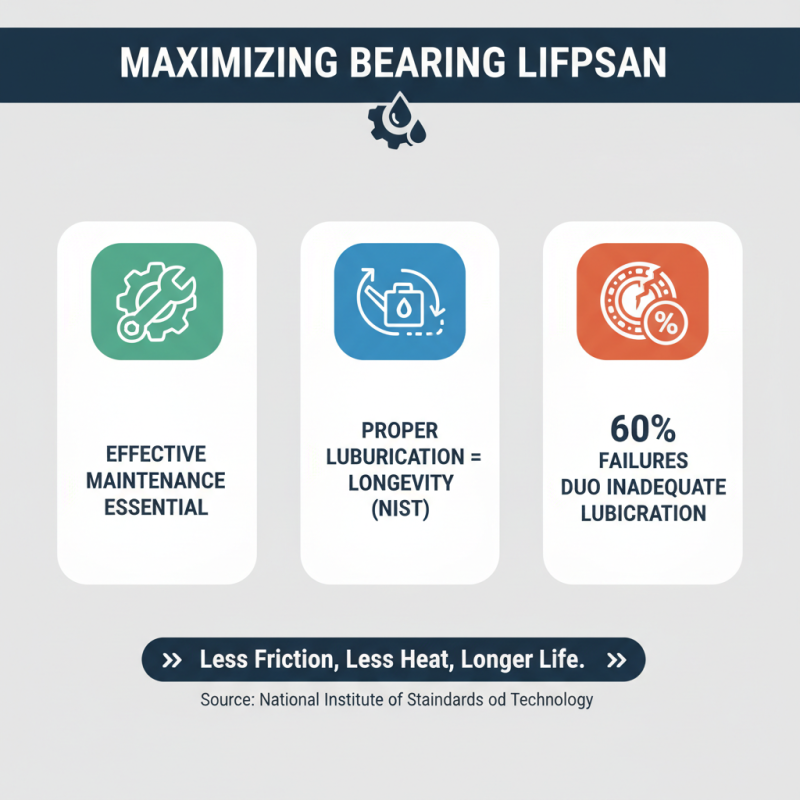

Maintenance Practices for Maximizing Bearing Lifespan

When it comes to maximizing bearing lifespan, implementing effective maintenance practices is essential. According to the National Institute of Standards and Technology, proper lubrication is one of the key factors that can significantly enhance the performance and longevity of bearings. Manufacturers estimate that around 60% of bearing failures can be attributed to inadequate lubrication. Regularly checking and replacing lubrication not only minimizes friction but also reduces heat generation, ultimately extending the lifespan of bearings.

**Tips:** Ensure that the right type and amount of lubrication is applied based on the specific operating conditions and bearing design. Use appropriate lubricants recommended for the application's temperature and load constraints.

Another vital aspect of bearing maintenance is the monitoring of operating conditions. Data from industry reports show that premature bearing failures often result from excessive vibration and misalignment. Routine checks and balancing can prevent these issues. Regularly inspecting the mounting and alignment of bearings can help detect early signs of wear and irregularities before they escalate into significant problems.

**Tips:** Employ vibration analysis tools to regularly monitor the health of your bearings. This proactive approach allows for timely interventions that can save costs on potential downtime and catastrophic failures.

Related Posts

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

2025 Top 10 Linqing Bearings: Discover the Leading Brands and Innovations

-

Top 10 Machine Bearings: Best Types for Optimal Performance and Longevity

-

Exploring the Science Behind Miniature Bearings and Their Role in Modern Technology

-

Top 5 Essential Pillow Block Bearings for Optimal Machinery Performance

-

Top 2025 Guide to Flange Bearings Applications and Benefits Explained

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat