Top 10 China Bearing Factory Insights for Quality and Production Efficiency

The manufacturing landscape in China has evolved dramatically, positioning it as a powerhouse in various industrial sectors, including the bearing industry. In the realm of precision engineering, the "China Bearing Factory" has emerged as a significant contributor to global supply chains, providing critical components that ensure the smooth operation of machinery across various applications. As the demand for high-quality bearings rises, these factories are compelled to refine production processes, focus on quality assurance, and enhance their overall operational efficiency.

In this article, we delve into the top insights related to China Bearing Factories that influence quality and production efficiency. By exploring the latest trends and best practices in manufacturing, we aim to shed light on how these factories optimize their processes to meet the stringent requirements of a competitive market. From innovative technologies and materials to workforce development and environmental sustainability, understand the multifaceted strategies that drive the success of China Bearing Factories in today’s economy. These insights not only highlight the significance of quality in bearing production but also underscore the vital role these factories play in supporting industries worldwide.

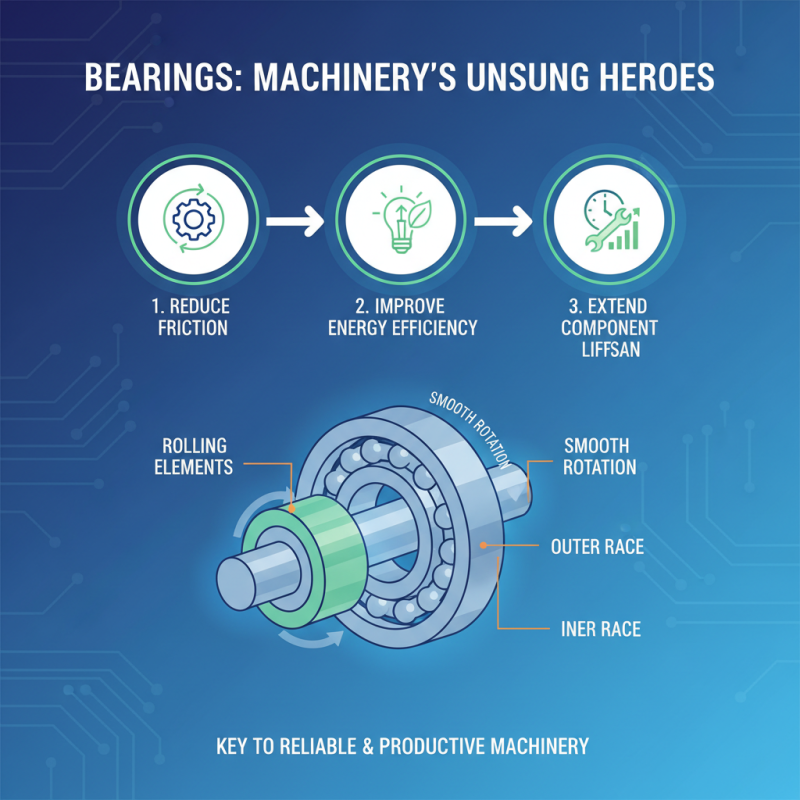

Understanding the Role of Bearings in Machinery Performance

Bearings play a crucial role in the performance of machinery across various industries. Acting as a support system, they reduce friction between moving parts, which is essential for efficient operation. When machinery operates with minimal friction, it not only improves energy consumption but also extends the lifespan of components. The selection of high-quality bearings can significantly enhance overall productivity by ensuring that equipment runs smoothly and reliably under varying loads.

Moreover, the design and manufacturing processes of bearings directly influence machinery performance. Precision engineering and stringent quality control measures in bearing production lead to products that can withstand high stress and operate in demanding environments. This optimization results in lower maintenance costs and reduces the likelihood of unexpected downtimes. Understanding the intricacies of bearing technology allows manufacturers to make informed selections, ultimately aligning with their production efficiency goals and ensuring superior machinery performance.

Key Factors Influencing Quality in Bearing Manufacture

In the competitive landscape of bearing manufacturing, ensuring high-quality output directly correlates with production efficiency. Key factors influencing quality in bearing manufacture include material selection, precision engineering, and rigorous quality control processes. A recent industry report highlighted that over 40% of bearing failures can be attributed to subpar material properties, underscoring the necessity for manufacturers to invest in high-grade raw materials. This investment not only minimizes defects but also enhances the durability and reliability of the final product.

Another critical insight is the importance of precision in the manufacturing process. Advanced machining techniques, such as computer numerical control (CNC), allow for exceptional tolerances and consistency in production. According to a study by the International Journal of Precision Engineering, enhancing manufacturing tolerances by just 0.01mm can lead to a 15% increase in operational efficiency. Manufacturers should regularly assess their technological capabilities to keep pace with market demands and foster innovation.

**Tips:** To proactively address quality challenges, factories should prioritize employee training on best practices in production and quality control. Implementing a continuous improvement program can also help in identifying potential quality issues before they escalate. Additionally, regular audits of the supply chain can ensure that all components meet the necessary standards, ultimately leading to enhanced product reliability.

This chart displays the impact level of various factors on the quality and production efficiency in bearing manufacturing.

Innovative Production Techniques for Enhanced Efficiency

In recent years, the bearing manufacturing industry in China has witnessed a remarkable transformation through innovative production techniques aimed at enhancing efficiency. According to a report by the China Bearing Industry Association, the adoption of automation and precision machining has significantly reduced production times by up to 30%. This shift not only lowers labor costs but also increases output quality, leading to enhanced customer satisfaction.

One of the most impactful techniques is the implementation of advanced robotics in assembly lines. These robots are capable of performing intricate tasks with high accuracy, minimizing human error in the production process. Industry data indicates that factories employing robotic automation have reported a 25% increase in overall productivity. Furthermore, integrating smart technologies such as IoT devices enables real-time monitoring of equipment, allowing for predictive maintenance that reduces downtime and extends machinery lifespan.

Tips for manufacturers aiming to enhance production efficiency include investing in staff training for new technologies and fostering a culture of continuous improvement. Regularly evaluating production workflows can uncover inefficiencies, while collaboration across departments often leads to innovative solutions that optimize processes. By embracing these strategies, Chinese bearing factories can continue to strengthen their competitive advantage in the global market.

Sustainability Practices in China’s Bearing Industry

Sustainability has become a pivotal concern in China's bearing industry, reflecting a commitment to environmental stewardship while maintaining production efficiency. As manufacturers strive to adopt more sustainable practices, many are investing in cleaner technologies and processes. This shift includes the implementation of energy-efficient machinery and the adoption of renewable energy sources in production facilities, significantly reducing carbon footprints. Such efforts not only contribute to environmental goals but also enhance overall operational efficiency, showcasing that eco-friendly practices can align with business objectives.

Moreover, the utilization of sustainable materials is gaining traction among bearing manufacturers. By sourcing recyclable and biodegradable materials, companies are not only reducing waste but also minimizing the environmental impact of their products throughout the supply chain. Additionally, the emphasis on better waste management methods, including recycling and reusing production by-products, reflects a broader trend towards circular economy principles within the industry. As the demand for greener products increases, companies that prioritize sustainability are likely to benefit from enhanced reputation and customer loyalty, paving the way for a more sustainable future in China's bearing sector.

Case Studies of Leading Bearing Factories in China

In the realm of bearing manufacturing, efficiency and quality are paramount. Leading factories in China have adopted innovative practices to enhance production while maintaining high standards. For instance, one factory implemented advanced automation technologies, allowing for precision in bearing assembly and inspection processes. This not only increased output but also minimized human error, showcasing how automation can streamline operations in the bearing industry.

Another factory focused on adopting a lean manufacturing approach, which emphasized waste reduction and process optimization. By analyzing workflows and employing just-in-time inventory management, they significantly improved efficiency. Regular training sessions for employees ensured that everyone stayed updated on best practices, fostering a culture of continuous improvement.

**Tips:** When looking to improve production efficiency, consider introducing regular training programs for staff to stay engaged and informed about new techniques. Exploring automation options can also lead to major efficiency gains while ensuring consistent quality. Lastly, adopting lean manufacturing principles can greatly assist in identifying and eliminating unnecessary steps in your production process.

Related Posts

-

2025 Top 10 Mounted Bearing Innovations You Need to Know

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

Top Linqing Bearing Applications and Benefits for Industrial Uses

-

Exploring the Future of Machinery: The Role of Cylindrical Roller Bearings in Enhancing Performance

-

Top 10 Tapered Roller Bearings for Optimal Performance and Longevity

-

2025 Top 10 Linqing Bearings: Discover the Leading Brands and Innovations

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat