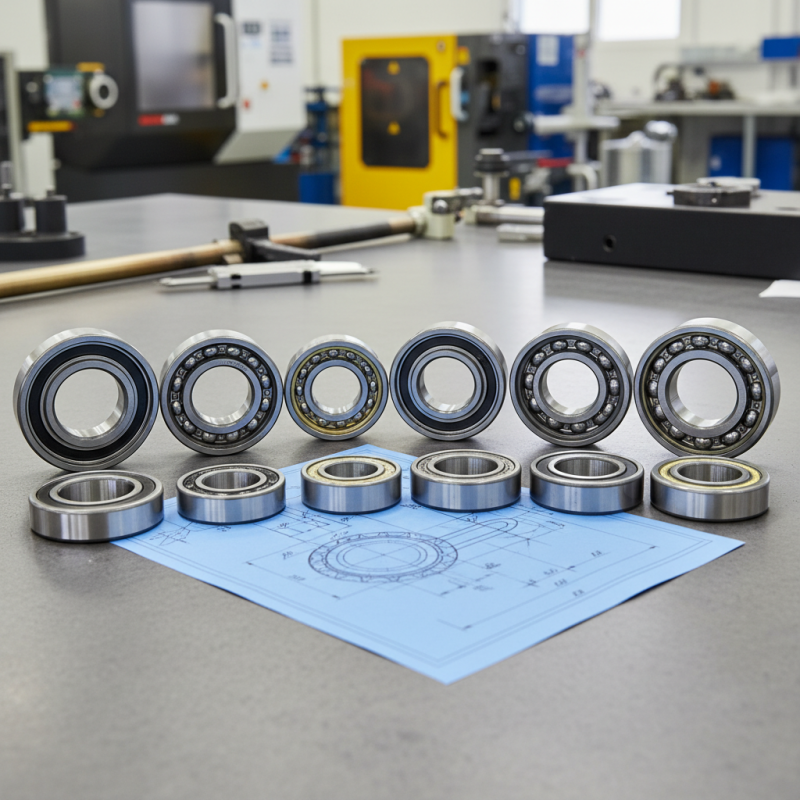

Top 10 Best Deep Groove Ball Bearings for Ultimate Performance?

Deep Groove Ball Bearings are vital components in numerous industrial applications. They offer high load capacity and low friction, contributing to enhanced efficiency. According to a recent industry report by the Market Research Future, the global bearing market is projected to reach USD 88 billion by 2026, with deep groove ball bearings leading in demand.

Choosing the right Deep Groove Ball Bearing can greatly impact performance. Factors such as material, size, and lubrication play critical roles. However, many users often overlook these elements, leading to premature wear and failure. A study published in the Journal of Manufacturing Science highlights that improper bearing selection can reduce a machine's lifespan by up to 30%.

In this guide, we will explore the top 10 options available on the market. Each bearing is evaluated based on performance and reliability. Engage with the details as we navigate through the intricacies of accuracy and efficiency in selecting the best deep groove ball bearings. Always remember, the right choice means improved productivity and reduced costs.

Understanding Deep Groove Ball Bearings: Basics and Functionality

Deep groove ball bearings are vital in numerous applications. These bearings are designed to handle both radial and axial loads. They consist of an inner and outer ring, balls, and a cage. The shape enables smooth rotation, reducing friction significantly. According to the Bearing Industry Manufacturers Association, these bearings account for around 90% of the bearing market.

A key factor in their performance is lubrication. Proper lubrication minimizes wear and prolongs the lifespan of the bearing. Industry reports indicate that improperly lubricated bearings can fail within months. This highlights the importance of regularly checking lubrication levels. Additionally, it raises questions about maintenance practices in various industries that rely heavily on these components.

Another aspect to consider is the load capacity. Deep groove ball bearings can tolerate moderate to heavy loads. However, overloading can lead to premature failure. Surprisingly, many users underestimate the effects of excessive loads. This can lead to costly downtime and repairs if not addressed. Analyzing load requirements beforehand can prevent these issues. Understanding these fundamentals is crucial for optimal performance.

Factors to Consider When Choosing Deep Groove Ball Bearings

When selecting deep groove ball bearings, consider several key factors. First, the load capacity is crucial. These bearings handle radial and axial loads. Too much load can lead to failure. Check the bearing's specifications for weight limits.

Next, the type of lubrication needed is important. Some bearings come pre-lubricated, while others require regular maintenance. This can influence performance and lifespan. Proper lubrication reduces friction and heat. It’s essential for smooth operation, but frequent checks are often overlooked.

Material quality also plays a significant role. High-quality steel can withstand wear and corrosion. However, cheaper materials might save money upfront but lead to premature failure. Lastly, the operating environment is a factor that needs attention. Dust or moisture can affect performance. Choosing the right seal type helps protect the bearings. Ultimately, finding the right balance takes time and careful evaluation.

Comparative Analysis of Leading Deep Groove Ball Bearings in the Market

The market for deep groove ball bearings is diverse and competitive. A comparative analysis reveals a range of options, each with distinct characteristics and performance metrics. Recent industry reports indicate that high-quality bearings can enhance efficiency by up to 30%, impacting overall machinery performance.

When selecting deep groove ball bearings, consider load ratings, material quality, and operational limits. For instance, bearings with a higher load capacity often maximize service life in demanding applications. Look for those made from high-carbon chrome steel, known for their durability and high wear resistance.

Tips: Always check the bearing’s precision grade. A higher precision can reduce friction and improve longevity. Regular maintenance is essential too; lubrication intervals should not be overlooked. Any neglect can lead to premature failures and costly downtime.

Maintenance Tips for Enhancing the Performance of Deep Groove Bearings

Deep groove ball bearings are essential in various machinery applications. Proper maintenance can significantly enhance performance and longevity. Regular lubrication is one key aspect. A lubrication frequency of every 500 operational hours can prevent wear. Many reports suggest that neglecting lubrication can reduce bearing life by up to 50%.

Monitoring operating temperatures is also crucial. Bearings should ideally operate below 70°C. If temperatures exceed this, it may indicate issues like insufficient lubrication or misalignment. Regular inspections can help identify these problems early. Visual inspections should focus on signs of wear, corrosion, or contamination.

Finally, cleaning methods must be chosen wisely. Often, improper cleaning can damage the bearing surfaces. Using ultrasonic cleaning is effective but can be costly. Simple methods, like wiping with a lint-free cloth, can be effective for regular maintenance. Yet, those methods might not remove all debris. It’s vital to find a balance between thorough cleaning and preserving the bearing’s integrity.