What is the Average Roller Bearing Price and Factors Affecting It

In the intricate world of industrial machinery, roller bearings play a crucial role in ensuring smooth operations and efficiency. Understanding the "Roller Bearing Price" is essential for manufacturers and engineers who rely on these components to maintain peak performance in their equipment. According to industry expert Dr. Michael Reynolds, a leading authority on bearing technology, "The price of roller bearings is influenced by a multitude of factors, including material quality, manufacturing techniques, and market demand."

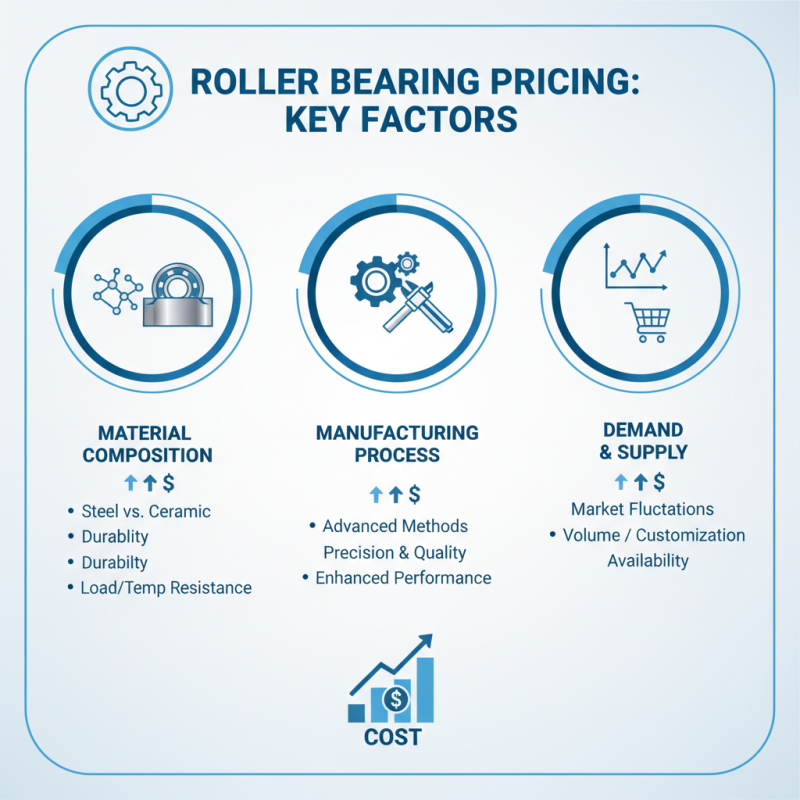

Variability in roller bearing prices can be attributed to various components, such as the complexity of design, the grade of materials used, and advancements in manufacturing processes. Additionally, fluctuations in raw material costs and shifts in industry demand can significantly impact pricing structures.

As businesses strive to optimize their operations, knowing what drives roller bearing prices becomes paramount. This understanding not only aids in budget forecasting but also empowers companies to make informed purchasing decisions. Hence, delving into the nuances of roller bearing prices and their influencing factors is essential for anyone involved in the sector.

Average Roller Bearing Price Overview

The average roller bearing price can vary significantly based on several critical factors, including the type of bearing, material quality, and manufacturing process. Recent industry analyses indicate that standard roller bearings typically range from $10 to $100, with specialized designs or higher precision bearings often costing upwards of $300. According to a report by Research and Markets, the global roller bearing market is projected to grow, leading to price fluctuations correlated with demand and technological advancements.

Material selection plays a vital role in determining the price of roller bearings. Bearings made from high-grade metals or advanced composites often exhibit better performance and longevity, hence their higher costs. Additionally, manufacturing processes such as precision machining and heat treatment also influence the final price. For instance, bearings requiring stringent tolerances may necessitate more costly production techniques, impacting the market price.

Tips: When considering a roller bearing purchase, evaluate your specific application requirements to choose the right type. Investing in higher-quality bearings may yield long-term savings by reducing maintenance and replacement costs. Always consult industry reports and supplier catalogs to stay informed about current market trends and pricing strategies.

Key Factors Influencing Roller Bearing Pricing

Roller bearing pricing is influenced by a multitude of key factors that merit careful consideration. First and foremost, the material composition plays a significant role in determining the cost. High-performance materials, such as steel or ceramic, may lead to increased prices due to their durability and ability to withstand higher loads and temperatures. The manufacturing process also affects pricing; advanced methods that enhance precision and quality can drive up costs. Attention to detail during production ensures better performance and longevity, making these bearings more expensive.

Another significant factor is the type of roller bearing itself. Different designs, such as cylindrical, spherical, or needle roller bearings, come with varying complexities and functionalities, influencing their price points. Market demand also affects pricing—higher demand typically leads to higher prices, while a surplus can result in discounts. Furthermore, geographical location impacts costs, as shipping expenses and local production capabilities can vary significantly from one region to another. Understanding these factors is crucial for buyers to make informed purchasing decisions in a competitive market.

Types of Roller Bearings and Their Price Variations

Roller bearings are essential components used across various industries, and their prices can vary significantly based on the type and application. There are several types of roller bearings, including cylindrical, spherical, and tapered roller bearings. Each type has its own unique characteristics that make it suitable for different uses. For instance, cylindrical roller bearings are primarily designed for high-speed applications, while tapered roller bearings are ideal for accommodating axial loads. This variation in design and application directly influences the pricing, which can range from a few dollars to several hundred dollars per unit.

When considering the purchase of roller bearings, it's important to assess not only the type but also the factors that can affect their prices. Material quality, manufacturing process, and load capacity are critical elements that contribute to the overall cost. For example, bearings made from high-grade materials like stainless steel may command a higher price due to their durability and resistance to wear. Furthermore, special treatments or coatings designed to enhance performance can also impact the final price.

Tips: When selecting roller bearings, consider not only the initial cost but also the long-term performance and reliability. It’s often more beneficial to invest in higher-quality bearings that may have a higher upfront cost but can lead to significant savings in maintenance and replacement over time. Additionally, always compare prices from multiple suppliers to ensure you’re getting a fair deal based on the quality and specifications of the bearings you're considering.

Impact of Materials and Manufacturing Processes on Costs

The cost of roller bearings is significantly influenced by the materials and manufacturing processes employed in their production. The selection of raw materials, such as steel or ceramic, plays a crucial role in determining both the performance and price of the bearings. For instance, high-grade steels that offer superior strength and durability can drive up costs, while more common materials may result in lower prices but potentially compromise performance. Additionally, specialized materials designed for extreme environments or specific applications can further increase prices due to their unique properties and the complexity involved in their production.

Manufacturing processes also contribute to the overall cost structure of roller bearings. Precision machining, heat treatment, and surface finishing are critical steps that ensure the proper functionality and longevity of the bearings. Advanced manufacturing techniques, such as automated processes and specialized tooling, can enhance efficiency and precision but may require a higher initial investment. Moreover, the scale of production impacts costs; larger production runs typically reduce per-unit expenses, whereas smaller batches may result in higher prices due to less favorable economies of scale. Thus, the interplay between material selection and manufacturing processes creates a nuanced pricing landscape in the roller bearing market.

Average Roller Bearing Price and Factors Affecting It

This chart illustrates the average prices of roller bearings based on material types and manufacturing processes, highlighting how these factors impact costs.

Market Trends and Their Effects on Roller Bearing Prices

The roller bearing market has experienced significant fluctuations in recent years, influenced by various trends that affect pricing. One major trend is the increased demand for high-speed and precision manufacturing processes across multiple industries, including automotive and aerospace. As companies invest in advanced technologies that require more sophisticated roller bearings, this rising demand places upward pressure on prices. Additionally, the push for greater energy efficiency and enhanced performance has led manufacturers to innovate, often resulting in higher costs associated with developing and producing specialized bearing solutions.

Another key factor influencing roller bearing prices is the impact of raw material costs. Fluctuations in the prices of steel and other essential materials used in bearing production can dramatically affect overall pricing. Supply chain disruptions, whether due to geopolitical tensions or natural disasters, can lead to scarcity of these materials, further exacerbating the situation. Additionally, environmental regulations aimed at reducing emissions and waste in manufacturing processes can also drive up operational costs, which are typically reflected in the end price of roller bearings. As these market trends continue to evolve, manufacturers and consumers alike must navigate the complexities of pricing in a dynamic economic landscape.

Related Posts

-

Top 10 China Bearing Factory Insights for Quality and Production Efficiency

-

Top Linqing Bearing Applications and Benefits for Industrial Uses

-

Top 5 Essential Pillow Block Bearings for Optimal Machinery Performance

-

2025 Guide: How to Choose the Best Miniature Ball Bearings for Your Project

-

2025 Top 10 Linqing Bearings: Discover the Leading Brands and Innovations

-

2025 Top 10 Mounted Bearing Innovations You Need to Know

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat